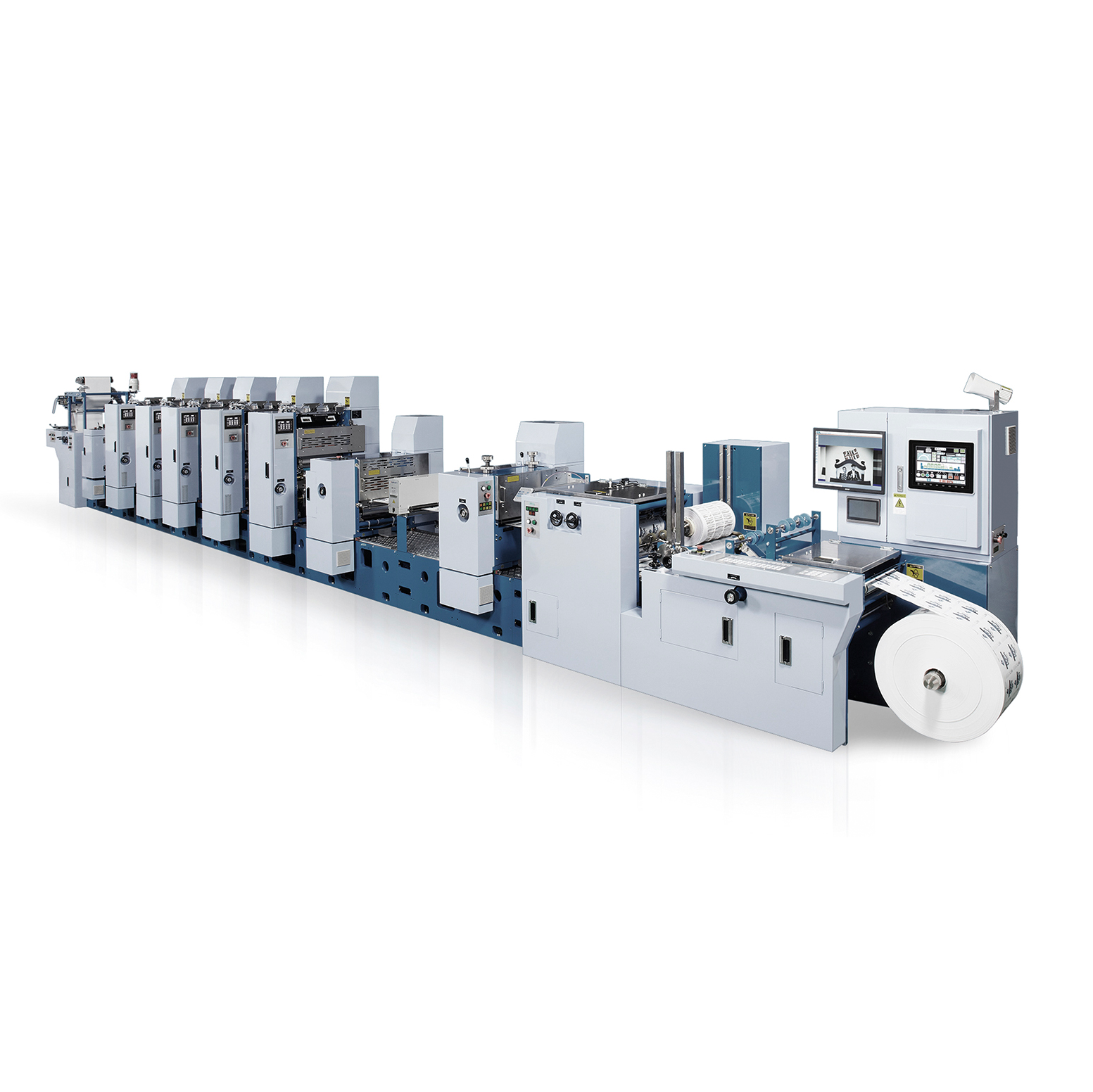

• Semi-rotary or ff set label printing designed to meet the increasing demand for small and medium runs with high quality and reduce start-up times and reduction of waste.

• Solid and robust construction.

• Its offset technology allows to obtain excellent print quality while reducing start-up costs to the maximum

• With up to 406.4mm repeat length, you get great flexibility in imposing labels, printing larger labels, and extremely high productivity.

• Maximum print speed of up to 300i / m, regardless of the repeat length, being able to print at that speed constantly.

• Each printing unit is controlled by a Bosch-Rexroth servo-driven motor and can work independently and / or synchronized.

• Quick change times thanks to its complete automatic electronic system

• Its patented tension control system, based on 2 servo-motor rollers in the unwinding unit and 2 in the rewinding unit, ensures precise registration and stable tension control at maximum speed.

Add-on modules:

1. Semi-rotary hot stamping module (Optional)

• Add value to labels.

• Thanks to its semi-rotary design and being equipped with an electric heater, preparation is very fast.

• Movie save mode is available as an option.

2. Flat screen printing module (Optional)

• It is an optimal solution for the printer who wants to carry out short, medium and long jobs thanks to the low cost of the screen.

• The screen moves back and forth while the squeegee remains stationary.

3. Semi-rotary Flexo module (Optional)

• There are two types available, open chamber and closed chamber.

• Both types allow adding value to the label during the printing process.

4. Demesh system with motorized shaft (Optional)

• Easy to prepare with good yield, this system improves productivity.

5. Lamination Unit (Optional)

• Possibility of working with a flexographic unit placed before the laminating unit to pre-glue the non-adhesive film.

6. Die with variable adjustment system (Gap system) (Optional)

• This optional system allows a precise adjustment between the base cylinder and the magnetic cylinder, thus allowing the use of the same cutting plate with materials of different thicknesses, saving costs and reducing the stock of tools.

7. Inkwell remote control system

• Electronic inkwell remote control system facilitates faster and more accurate color adjustment.