| Brand | |

|---|---|

| Sectors |

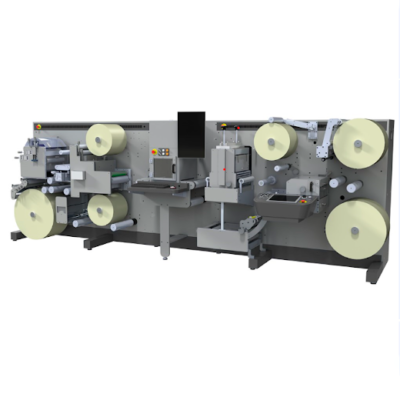

MBO SVC 23 re-moulding machine: high performance in web finishing

The resmadora MBO SVC 23 (23") is the most advanced modular solution in the line of coil-fed finishingdesigned for high-speed cutting of a wide variety of products. With a design focused on efficiency, the SVC 23 guarantees increased uptime, flexibility and ease of useThis translates into added value for any commercial printing environment.

His touch screen interfacethe improved system of scrap disposal and simplified access to tools make configuration faster and without the need for manual adjustments. In addition, features such as the programmable cutting length, multi-job memory and cassette-type cylinder design facilitate maintenance and optimise workflow.

Built with robust components and designed for print environments 24/7the SVC 23 is ideal for the continuous processing of inkjet web-fed printingoffering reliability, versatility and superior performance.

Key features of the SVC 23

-

Superior web control thanks to continuously driven infeed rollers

-

User interface with touch screen on swing arm

-

Wide variable and programmable cutting range

-

Memory for hundreds of jobswhich speeds up the preparation and repetition of runs.

-

Edge trimming with integrated ejector tubes

-

Registration system using print mark on the band

-

Double cutting cylinder design for maximum precision

-

Programmable chip output configuration

-

Optimised debris removal through the central blade cover

-

Air-assisted paper flow for more efficient handling

-

Cassette type cutting cylinderremovable for easy access and maintenance

The SVC 23 of MBO is the ideal reamers for printers who are looking for increased speed, reduced downtime and consistent quality in coil slitting and finishing processes. Its modular design ensures productivity and long-term value in the competitive commercial printing market.