| Brand | |

|---|---|

| Sectors |

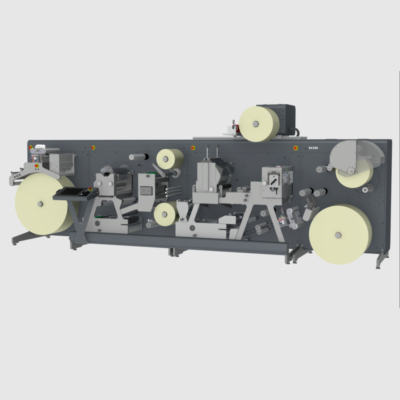

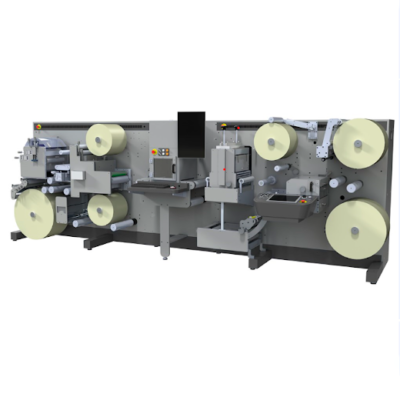

MBO UW 23 Unwinder: coil feed with maximum precision

The MBO UW 23 Unwinder is a coil feeding unit of up to 23″ wide and 52″ in diameterdesigned to ensure a constant and precise unwinding in printing and finishing processes. In web production, it all starts with the right paper delivery, and the UW 23 ensures the right paper is delivered to the right place. stable tension and accurate guidance at all times.

This unwinder incorporates a tension control system with roller dancers and a motorised spindle provide optimum control, even with large and heavy reels at maximum speed. In addition, it integrates splicing table, electric paper lifter and anti-curl deviceThis improves output quality and reduces set-up times.

His sturdy steel construction and heavy duty roller drive offer maximum reliability, long service life and dependable performance in continuous operations 24/7.

Main features of the UW 23 Unwinder

-

Ideal for solutions offline or near-line

-

Coil capacity up to 52″ diameter for longer production time

-

Large diameter rollers to reduce curling and tension disturbance

-

Quick coil change thanks to quick release chucks

-

Precise unwinding control even with full reels at full speed

-

Integrated splicing table with guides and clamps to reduce setup times

-

Electric paper elevator that minimises occupational hazards and speeds up roll changes

-

Pneumatic dancer rollers ensure the best possible tension control

-

Integrated band guide for precise delivery to the finishing system

-

Device for curl removal to improve the quality of printing and finishing

Available options

-

Splice sensor to prevent factory connections from being passed on to downstream processes

-

3″ or 5″ diameter core shafts

-

Right-angle configuration with WTS air bar

-

Possibility of integration inline with OEM presses

The MBO UW 23 is the ideal solution for printers and finishers who are looking for maximum productivity, precise voltage control and continued operational reliability.