BAUMANN

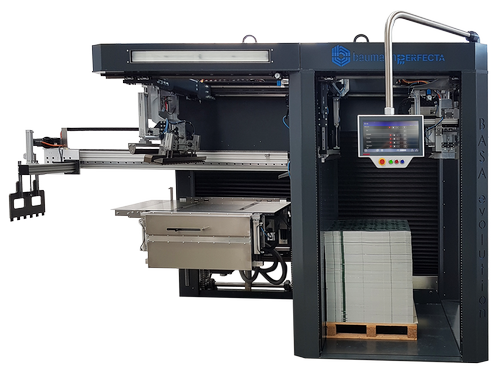

Baumann Gruppe is one of the largest companies in the post-press machinery and systems sector for the graphics industry. German manufacturer of cutting lines and systems.

baumannwohlenberg and PERFECTA, have a long tradition and have successfully established themselves in the world market as leaders in innovation and technology. With the merger of the baumannperfecta belts, we have also merged the strengths and core competencies of these two companies from the Baumann Gruppe.

perfect baumann was the first and only manufacturer within the graphics industry in automate the vibration and equalization process, as well as the cutting process, ensuring operation without human intervention, in three shifts, 24 hours a day.

Its product range includes, among others, equipment and peripheral machinery to its cutting guillotines (elevators and battery loaders, air tables, vibrators and pile equalizers ...) as well as pile turners and other equipment for printers.

Fill in the form and we will contact you as soon as possible with all the information

In addition, in 2018 baumannperfecta launched the BASS system, the first robotic solution based on current industrial robots within the finishing area of the graphics industry. The importance we attach to new technologies is also reflected in our departments of Investigation and development. With approximately 200 employees and a percentage of approximately 20% in mechanical engineering, this is above average.

I'M INTERESTED