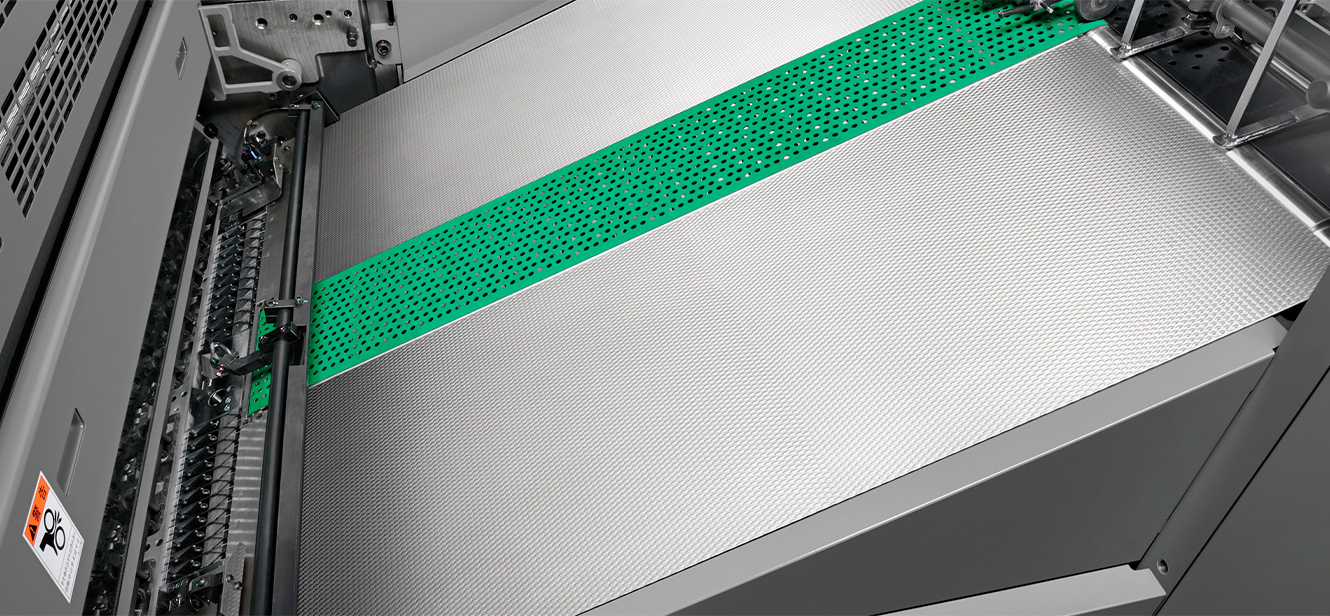

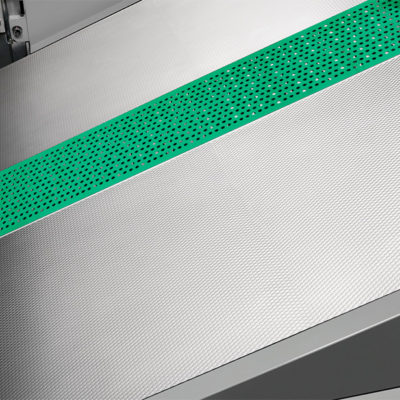

Marker with suction tape

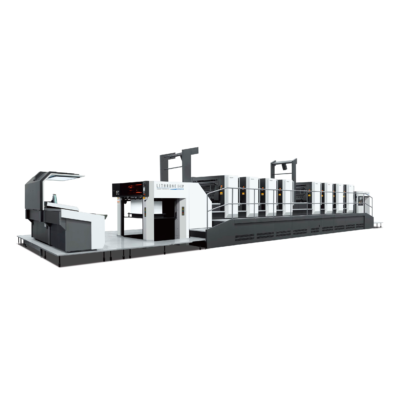

A new board with a belt in the center and the absence of brushes or rollers ensure stable and accurate sheet feeding regardless of paper quality or size. This improves stabilization of sheet surface behavior, paper path, and precision and ease of handling. Since the Lithrone G40 easily accepts thick sheets, the time required for changing paper sizes is reduced.

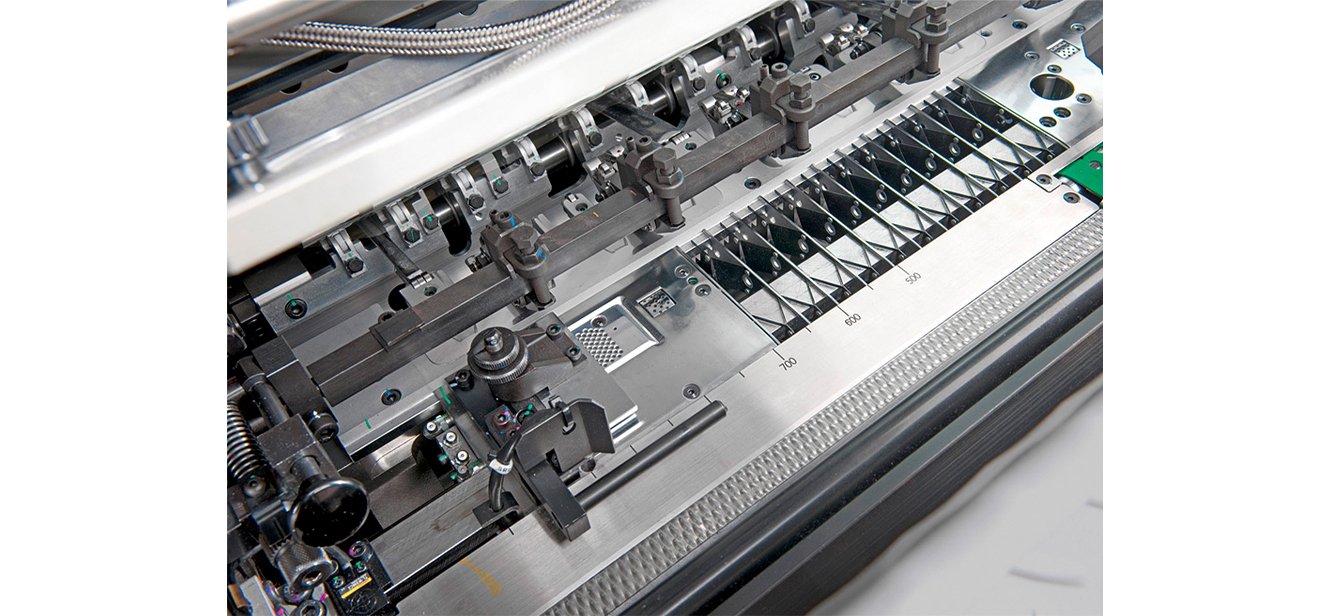

Pneumatic side guide and front heel

A vacuum design is used to ensure the accuracy of the guides, which is also a solution to roller markings. In addition, adjustments can be easily made to suit the type of paper during the run. Improves the stabilization of the paper in the register.

Suction head

The suction head improves sheet separation and stable high-speed feeding thanks to the extension of the elevator travel and the arrangement of the suction line.

Side jogger linked to sheet size

Sheet output has been improved with a side jogger expansion / contraction feature. Thanks to its adaptation to the presetting of the sheet size, the lateral jogger expands / contracts not only laterally but also on the vertical axis, improving the alignment of the sheets with different sheet sizes.

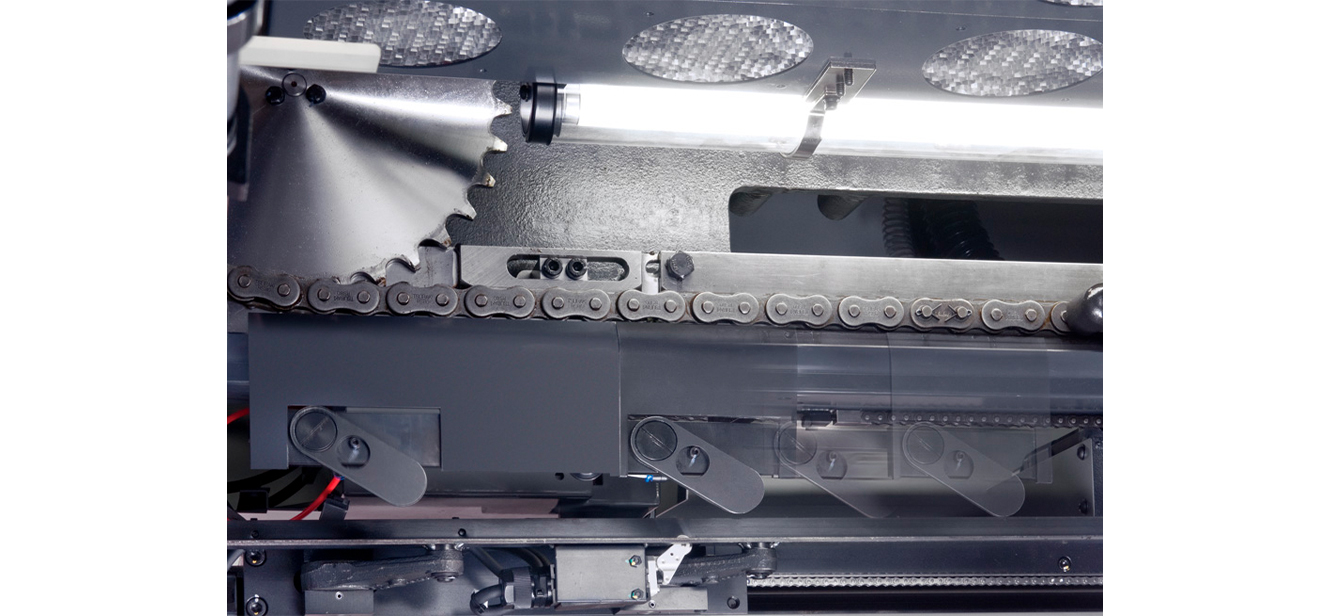

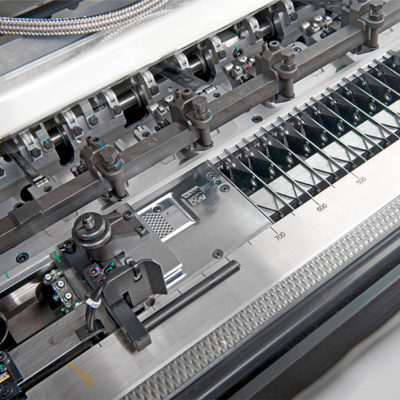

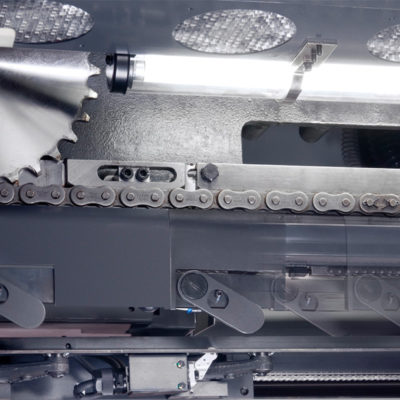

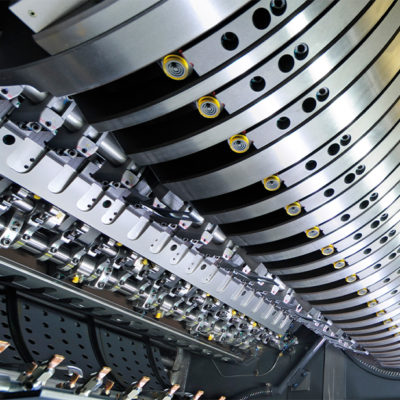

Departure

As a result of rail improvements and changes to the air control system, blade behavior is stabilized by optimizing the shape. The stabilization of the sheet transport facilitates a very stable output of sheets at high speed.

Automatic cleaning systems

Efficient and automatic cleaning thanks to an automatic control program. The fastest automatic rubber cleaning system on the market improves thanks to the use of a pre-moistened fabric for washing the rubbers and cleaning the pressure cylinder. This shortens cleaning time and also protects the environment thanks to less fabric consumption. Komori automatisms link all these processes to considerably shorten the overall set-up time. In addition, the lower position of the impression cylinder cleaning systems (which can be easily removed from the control side) facilitates the change of the fabric and improves maintenance comfort.

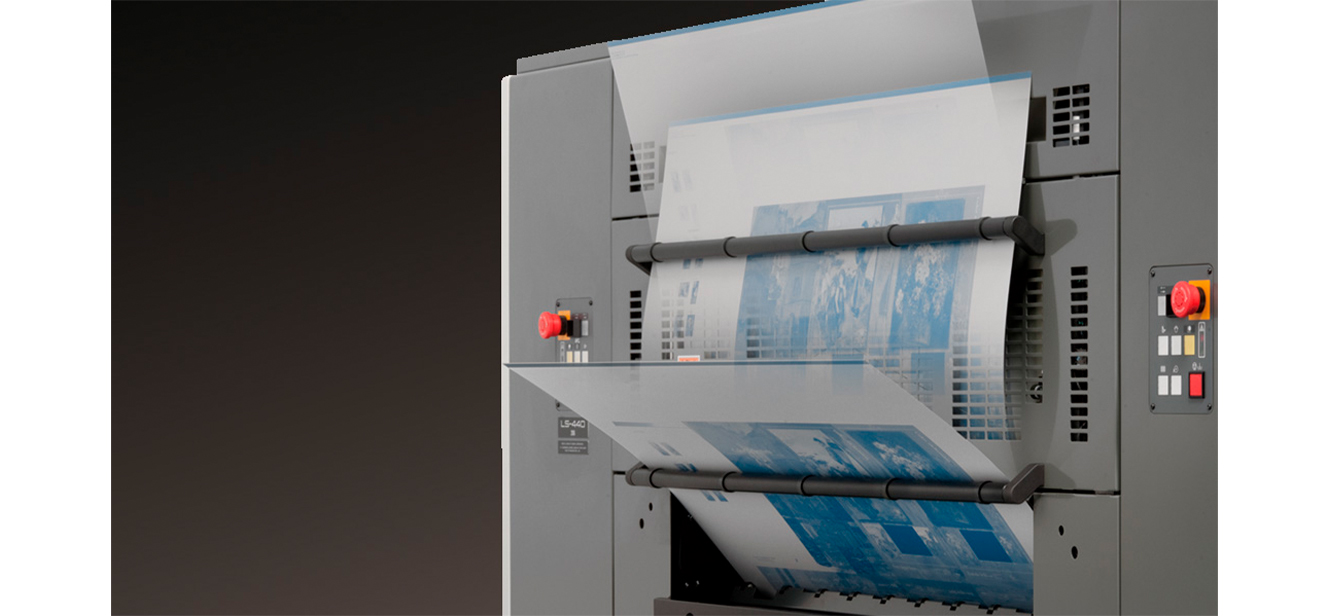

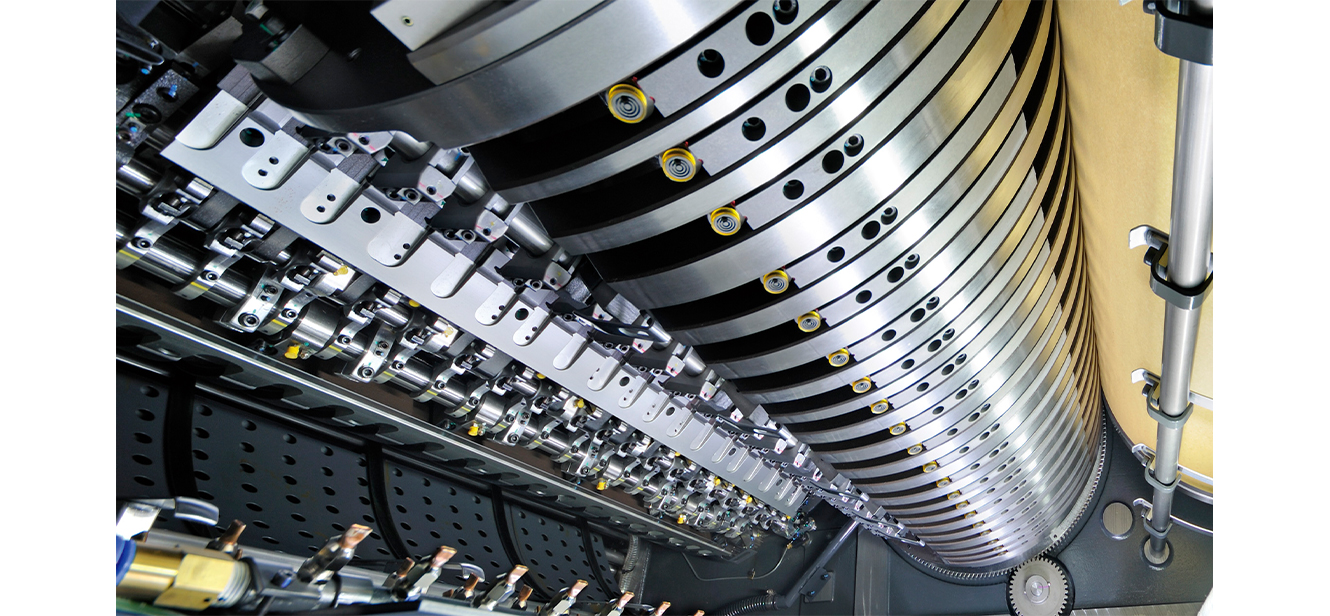

Full-APC, automatic plate change

The new Full-APC system is not only faster than previous systems, but also employs a no-bend jaw, eliminating the need to bend plates and making plate loading and unloading more efficient. Flat clamping also improves registration accuracy and shortens setup times.

A-APC, asynchronous plate changing

When equipped with the asynchronous automatic plate changing (A-APC) system, set-up on the Lithrone G40 is substantially shortened, to just 1 minute and 25 seconds for plate changing.

Three double bore cylinders

Double diameter cylinder configuration with double diameter impression, transfer and removal cylinders.