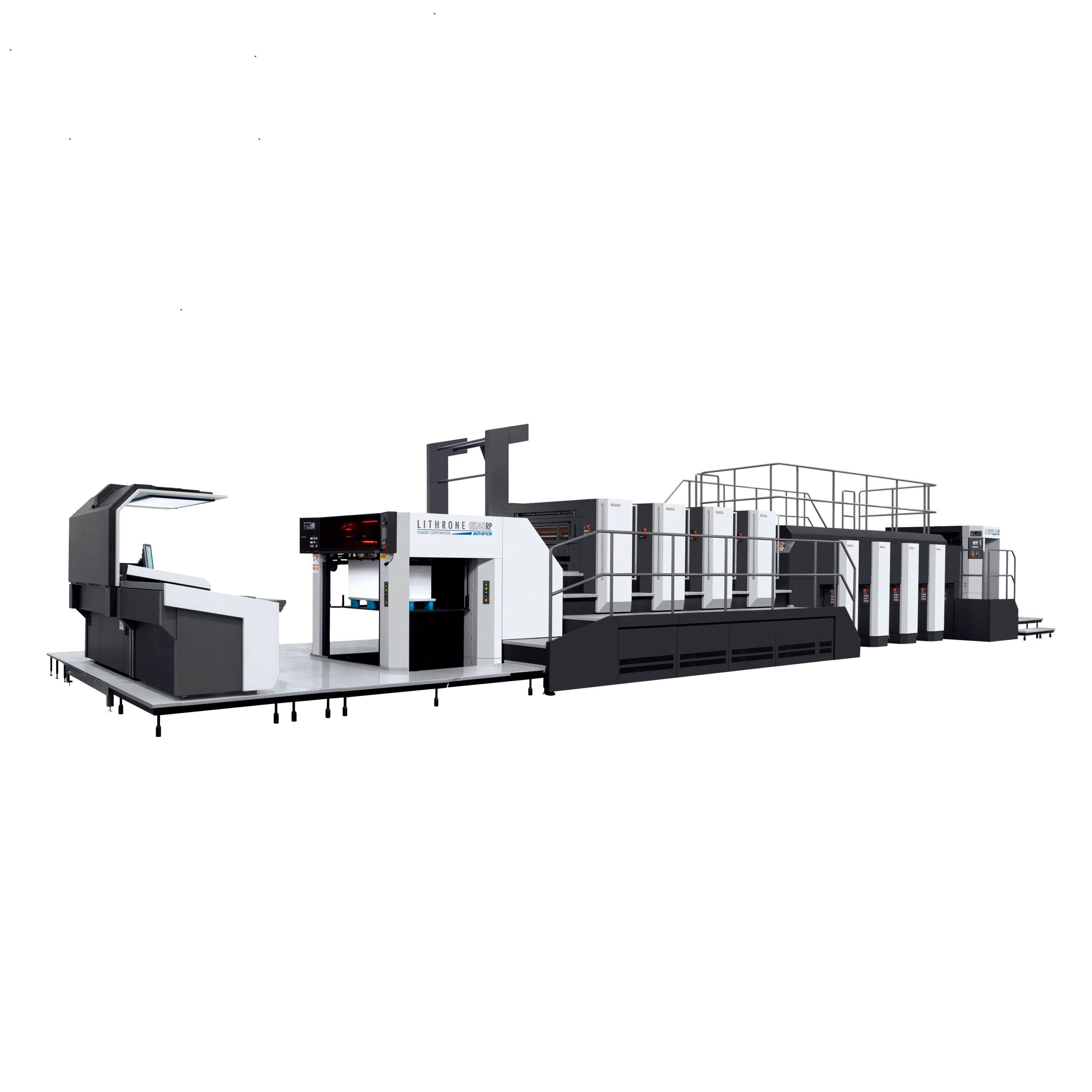

The latest no-flip double-sided printing press compatible with the OffsetOnDemand concept follows the philosophy of the Lithrone G series.

The 44-inch GX44RP can be equipped with different UV drying systems *.

It is designed to offer high quality, short lead times, high speed, stability, and reduced waste in double-sided printing.

The new single edge grip system eliminates sheet flipping. This grip system makes the necessary margin at the end of the sheet - an unavoidable requirement in turning machines -, completely unnecessary, which allows to reduce paper costs by minimizing the size of the sheet. Elimination of blade tipping ensures stable transport being able to handle light or heavy materials through the use of four double size transfer cylinders. Front / back imaging is done in the same direction as with single-sided presses, increasing efficiency in prepress.

This machine expands the world OffsetOnDemand by means of a short set-up and instant dry without powders makes it a very interesting option for short runs and reduced lead times thanks to the integrated KHS-AI * 1 start-up control system and to the UV curing system *. . In addition, this press can be optionally equipped with the A-APC asynchronous automatic plate changing system, the PDC-SX spectral print density control system and the PQA-S print quality system for sheets achieving even higher levels. quality and productivity.

The Lithrone GX44RP stands for: state-of-the-art technology and knowledge to achieve automation, standardization and innovation in printing. A powerful platform for the new generation of printing companies.

It can be equipped with the following drying systems: H-UV • H-UV L (LED) or UV