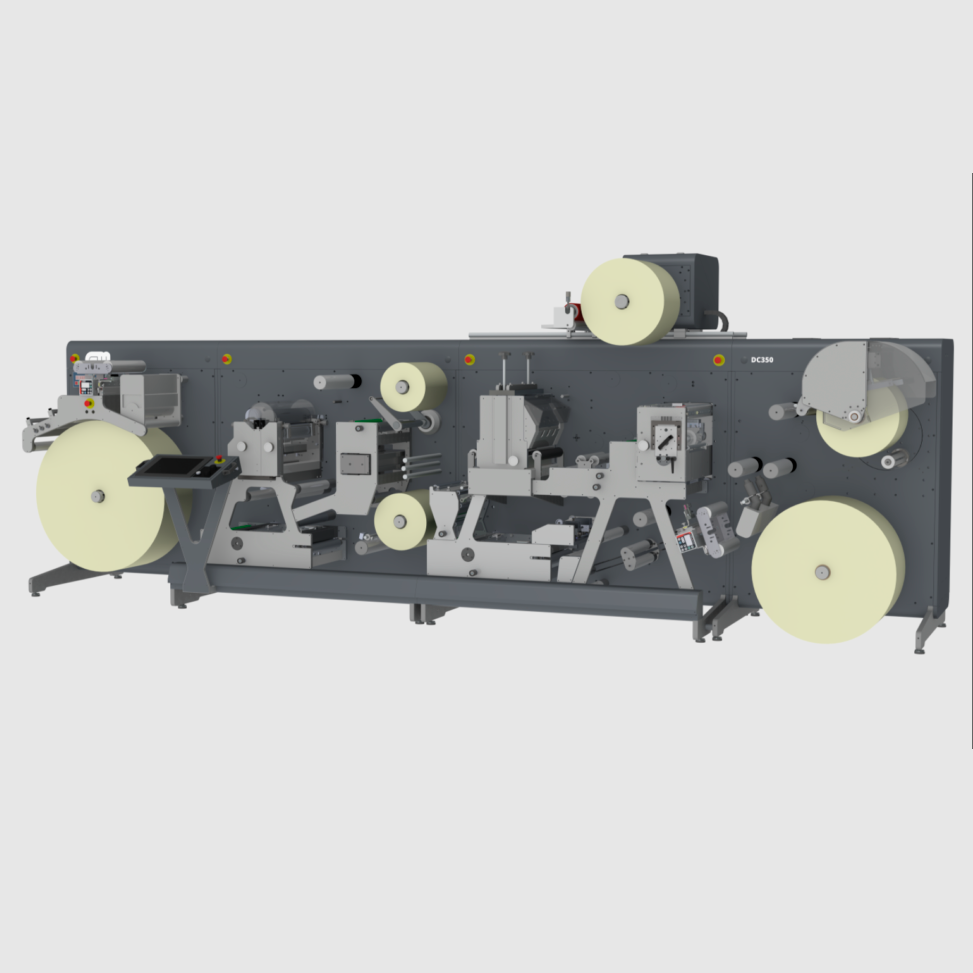

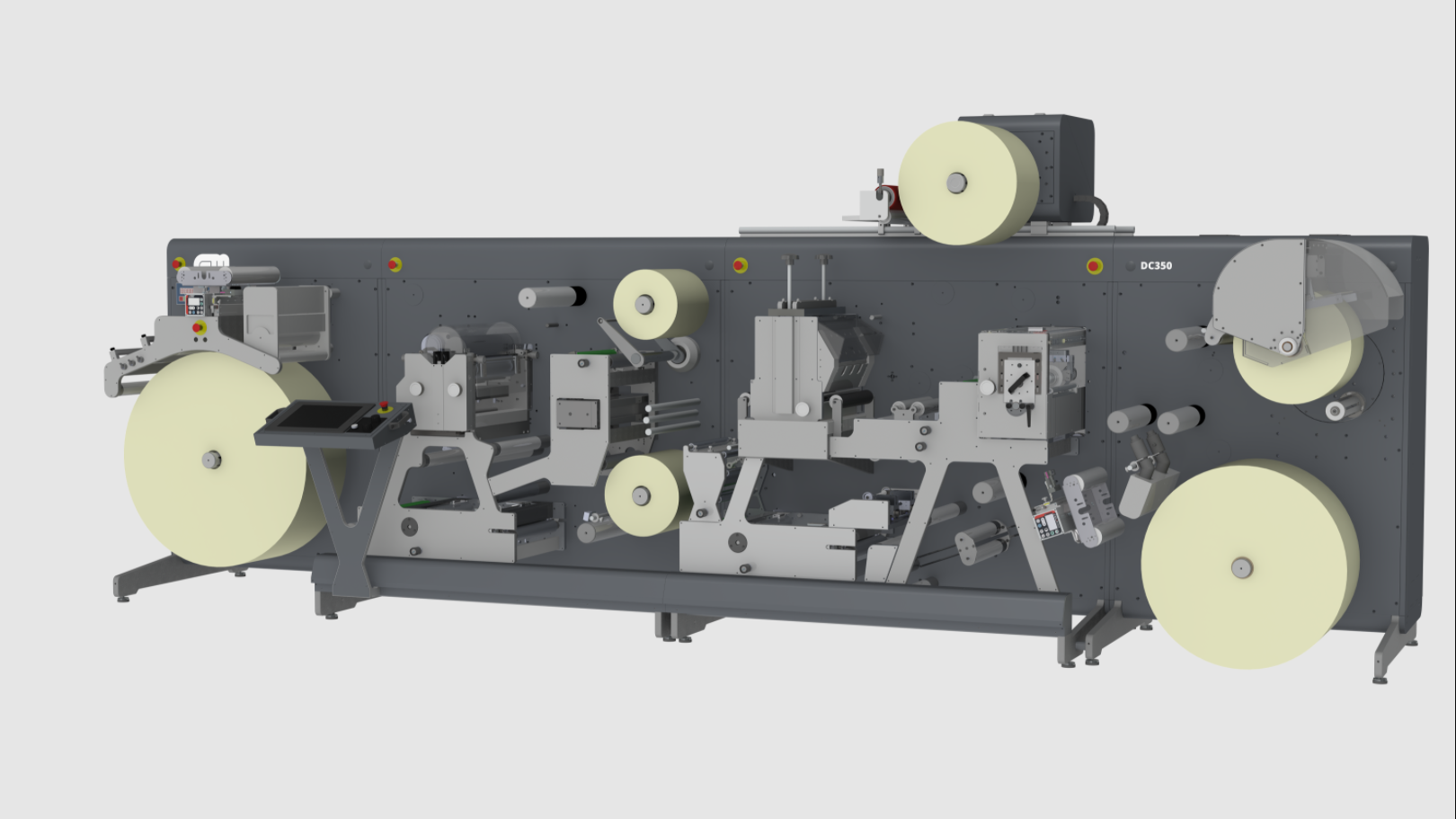

PRODUCT INFORMATION

Laser module

Ideal for short-run, on-demand production, the GM laser cuts a wide range of substrates and can be added to existing systems in just days. With a minimal spot size and optimised wavelength, the laser's melting edge is minimised to eliminate burn marks. The module can be fully connected to the cloud and integrated into your MIS for an automated workflow. The optional QR barcode reader enables hands-free automated job changes.

SmartFlexo

Add 1, 2 or 3 flexo modules to the configuration for more value-added options. Modules can be configured as semi-rotary or full rotary re-register groups and are designed for flood varnishing, cold lamination or colour specific printing.

Hot Foiling

The 50 tonne hot foil module uses multiple foil streams and features a rotating tower for the largest possible design options. This all-in-one solution allows embossing and foiling in one process. It comes with built-in foil shield and electronic temperature control, while dwell time and speed can be digitally fine-tuned.

Screen-printing

Essential for the production of wine and other high-value labels, the servo-driven precision flatbed screen printing unit can add thick varnishes, print custom spot colours, create scratch effects and much more. The module can be equipped with cost-effective and widely available frames and features a large UV reflector lamp for fast and effective drying. Multiple screen printing heads can be installed on each line.

Die-cutting

The semi-rotary die cutting module is at the heart of our finishing lines. As standard, it comes with automatic registration and plate distortion adjustment for full use of older plate inventory. Optionally, it can be equipped with a plate loader and the automatic GapMaster function. The die has a standard stroke of up to 25" and supports even the largest labels. The standard unit can be replaced with our double-speed die module, which has a maximum speed of 140 m/min. Conventional waste matrix removal and rewinding can be upgraded to GM's servo-controlled SmartStrip system.

Rewind

In short run production, the operator spends a lot of time at the rewind station, so we have paid special attention to this area by adding continuous tension and user-friendly quick change mode with pneumatic air shafts. The rewind section can be configured with either a standard twin rewinder or a turret rewinder. In turret rewind mode, there is a choice of semi-automatic (operator web slitting) or fully automatic (automatic slitting). With a changeover time of less than 10 seconds, this is one of the fastest systems on the market.