Quality

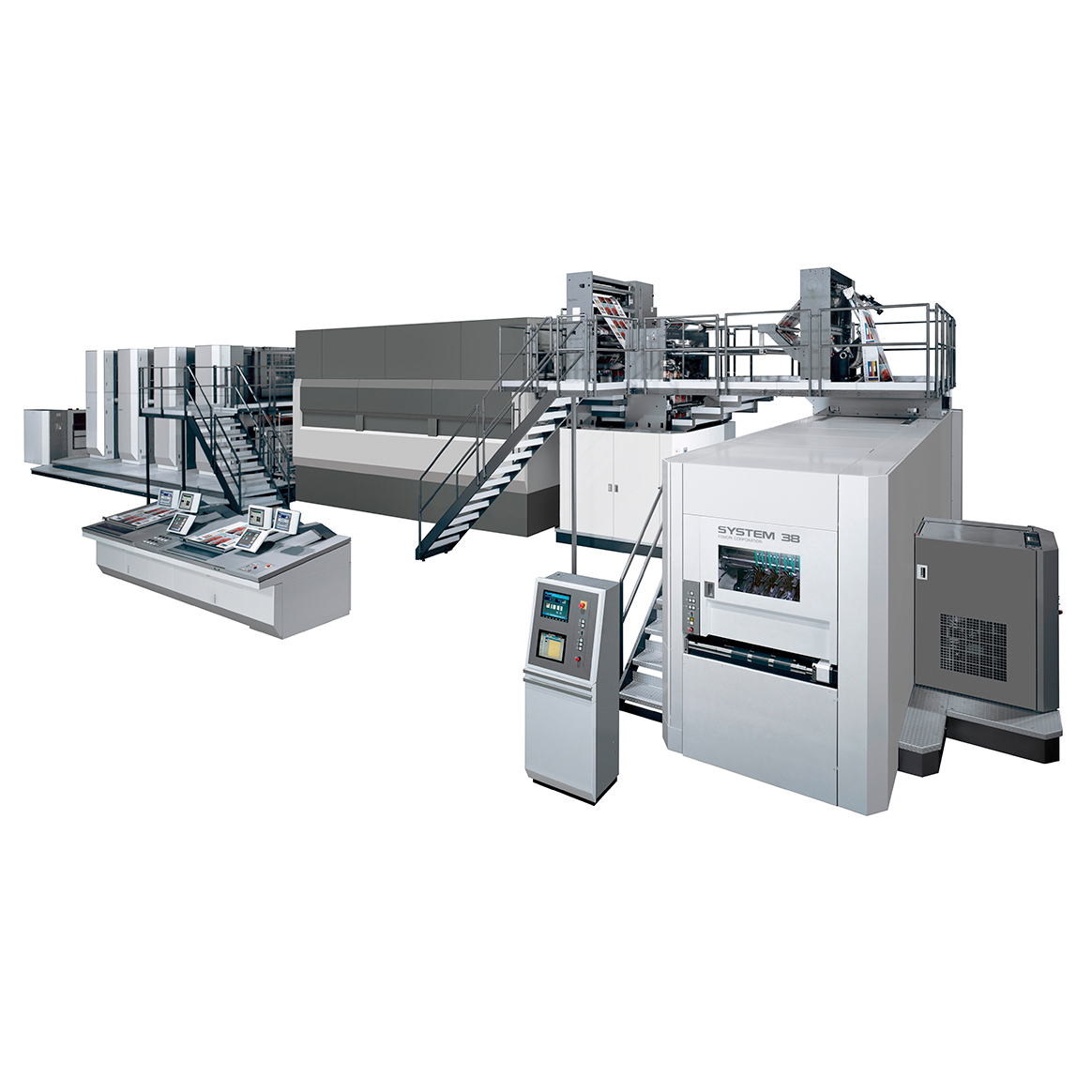

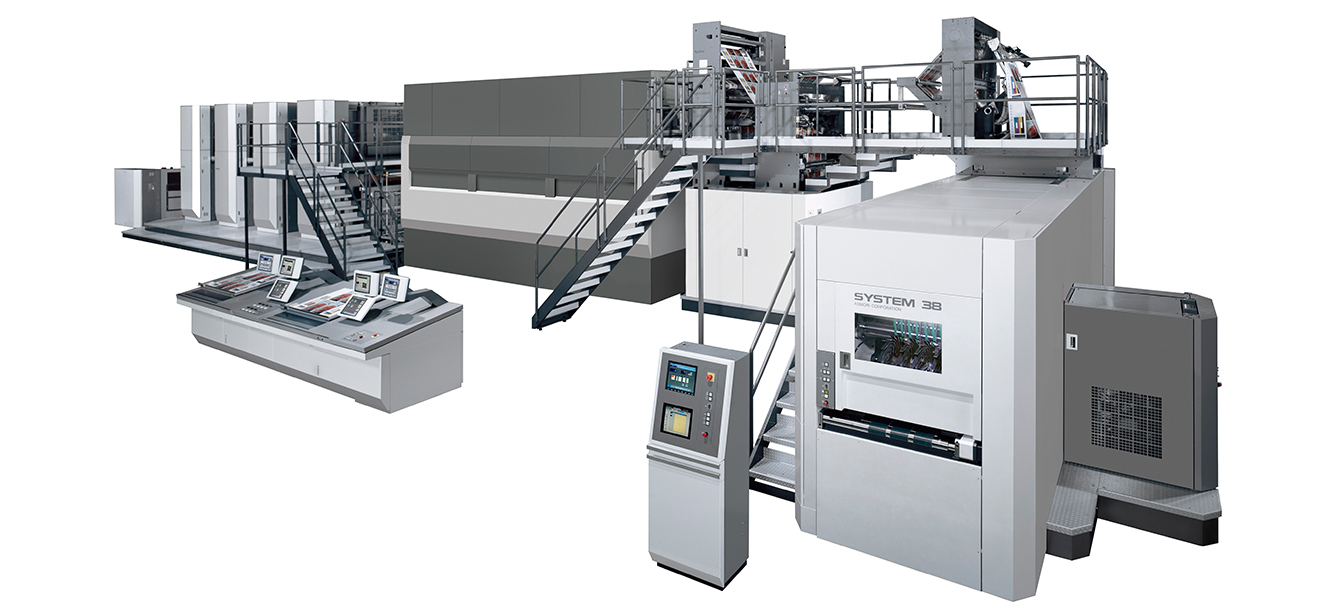

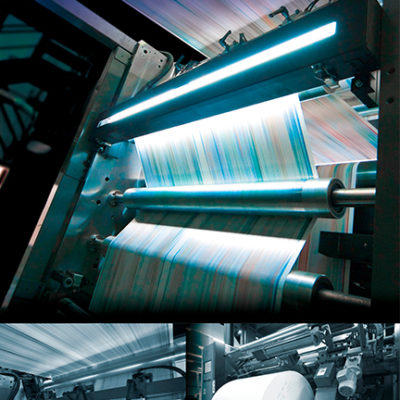

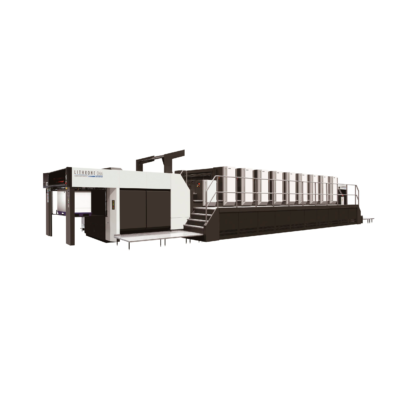

The superior print quality of the Komori System 38 press is a fact.

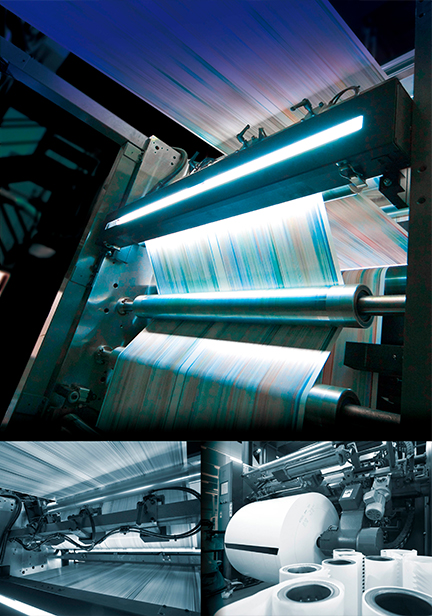

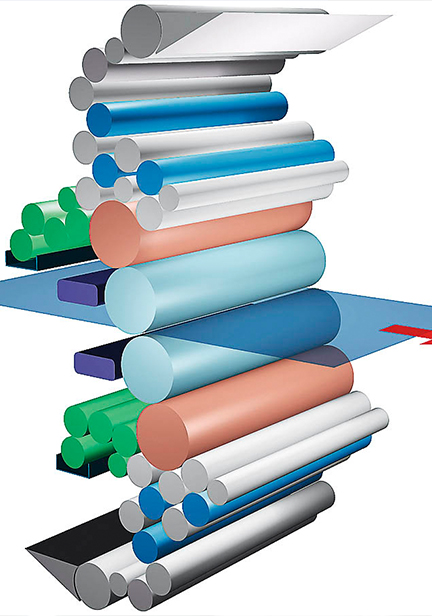

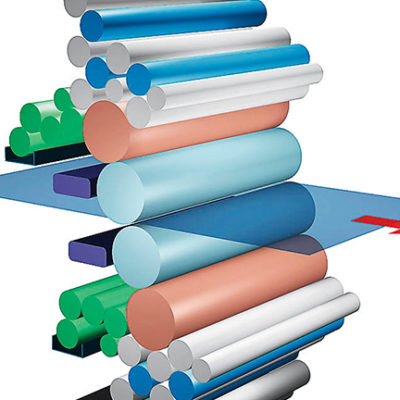

The key is the single double diameter rubber cylinder assembly and oversized plate cylinders and ink rollers, ensuring complete stability and perfect paper flow.

The ink fountain design, fountain system and automatic registration guide function employ the proven technologies of the System 38S to ensure high print quality.

The motorcycle handrail is motorized and the inking and dampening rollers use an innovative oscillating design.

Digital control executed from a state-of-the-art control console offers simple operations, allowing the machinist to dedicate himself to the task of quality control.

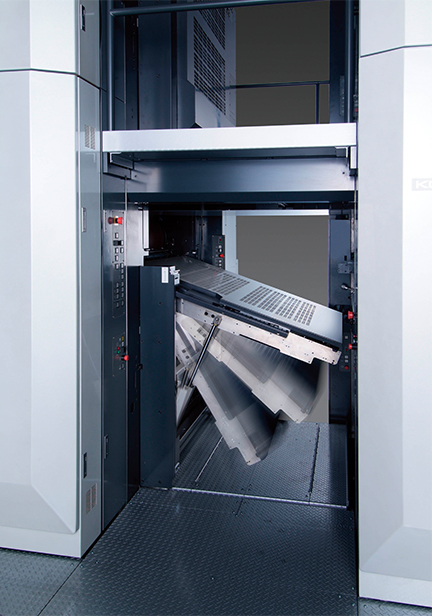

Provides high bending precision with the DC-38/1250 double-blade folder. The folding format change is integrated into the KHS-AI system and is fully automated.

The cutter cylinder with take-up function ensures a perfect fit of folded products. The high technology of the System 38S makes the quality difference in the 32 page press market.

Productivity

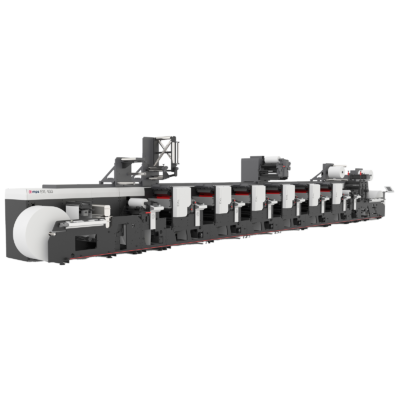

Komori's revolutionary fully automatic plate changing system (Full-APC) makes the System 38D the most advanced 32-page short-run press.

The Full-APC automatic plate system allows a single machinist to change all eight plates in less than three minutes - time and labor values that really increase productivity.

The machine has been designed to maximize the efficiency of the Full-APC with easy adjustment of the plates and a wide space between the printing units for the operator. And the high precision of the plate feeder takes full advantage of the cutting-edge technology of CTP systems.

To streamline job changes, the System 38D employs an Intelligent Sequencing System for simultaneous execution of change jobs based on job data.

In addition, it uses the Synchronized Drive System, which accelerates the machine quickly, allowing the operator to start printing also quickly. Both systems have a significant impact on the cost of short-run work, with considerable savings in time and labor.

Technology

The productivity achieved by the System 38D is due to Komori's high technology, printing at 39,000 iph.

Still, the imperative handling of short runs makes quick setups just as important.

The System 38D performs start-up in much less time than other 32-page presses on the market.

The KHS-AI (Commissioning Interface) system achieves this brilliant performance, based on Komori's Do-Net with a built-in autotune function, standard on the System 38D.

K-Station sends the work order, including the paper specifications, inking profile and folding format to the KHS-AI, which then searches its database for the optimal parameters for the operation of the machine, controlling the guides, tensions , dryer settings and other variables.

The machine makes the pre-adjustments even before starting the print job. KHS-AI's Auto-Tuning feature facilitates optimal pre-programming by continually analyzing color settings and offset values that vary based on facilities, paper type, other media, and even the customer.

This analysis is used for a continuous update of the KHS-AI database to provide the best preset data for all items from ink screw openings to blade timing. The fastest and most accurate 32-page press ever.

Reliability

Komori is aware of the maintenance required for a 24/7 large production machine like the System 38D and has designed an intelligent technology support system in the easy-to-use KHS-AI system on the control console.

Komori also deploys a network of online technical engineers, strategically located parts depots, and technical service to ensure prompt assistance in any situation. The reliability is total.

The machine has an advanced self-diagnosis system that allows quick troubleshooting and maintenance control, and also has an error log. KHS-AI supports the operator in handling the press.

And the remote control allows Komori to “see” inside the networked machine, when remote control is performed and service is required. Beyond the hardware and software, Komori has the people and infrastructure to keep the System 38D running constantly.