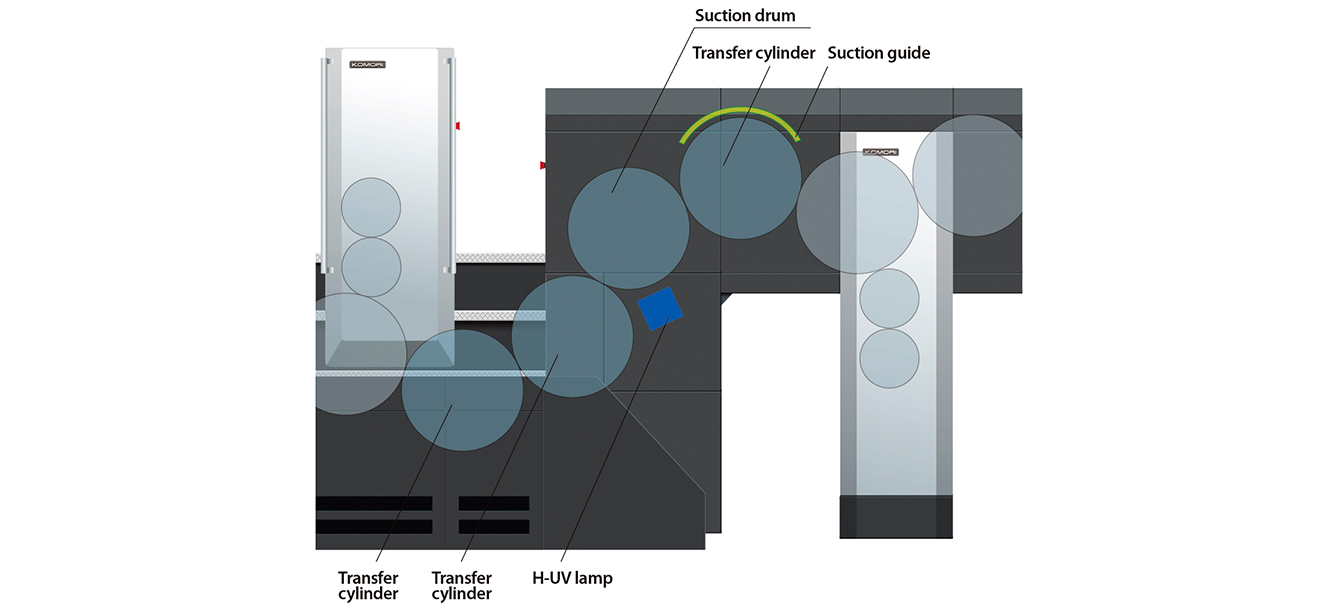

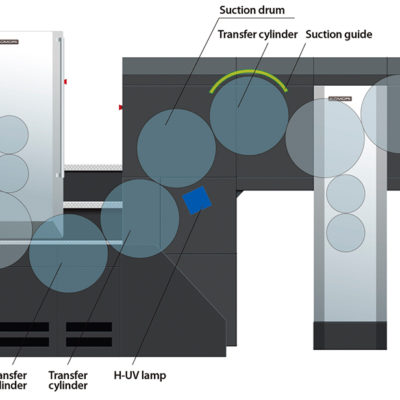

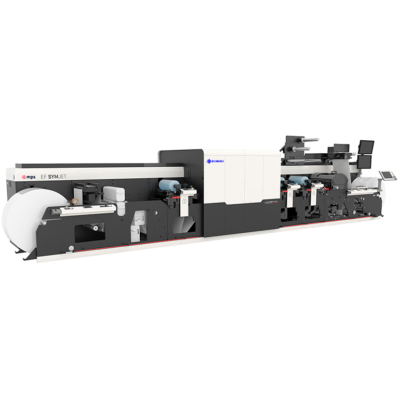

Eliminating sheet flipping ensures stable paper transport, compatible with high and low weight materials through the use of four double diameter transfer cylinders.

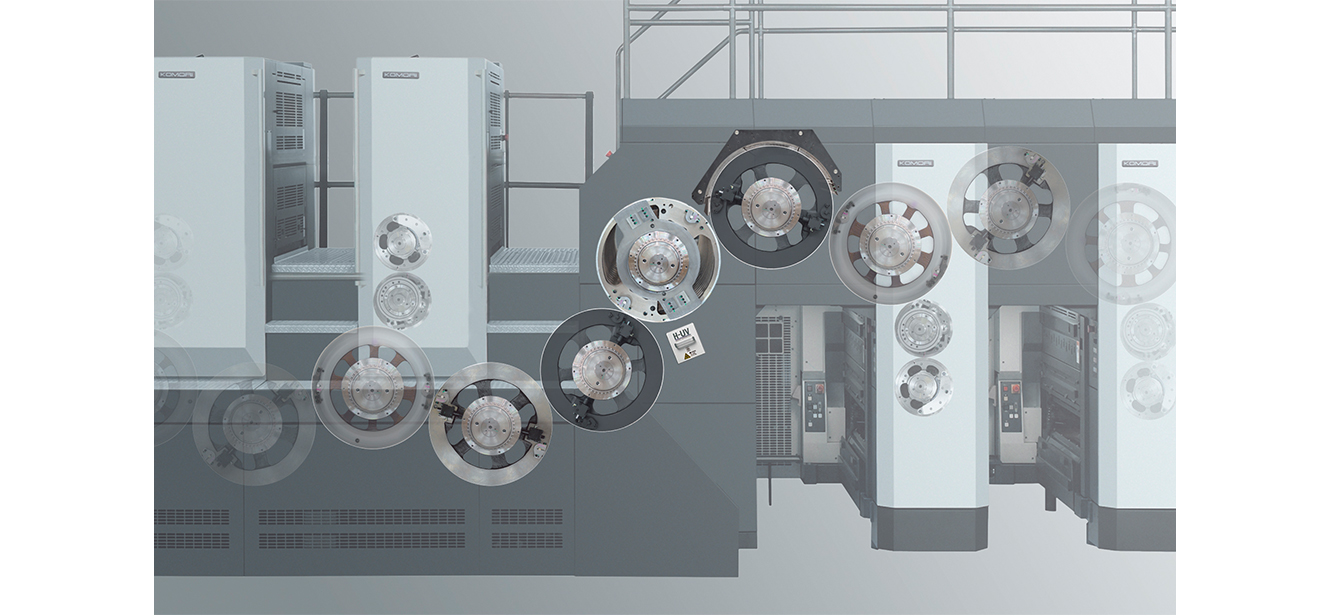

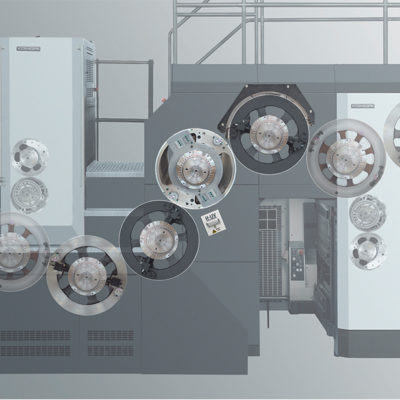

The exposure of the front / back plates is done in the same direction, as in the machines that print on one side, improving the efficiency of prepress.

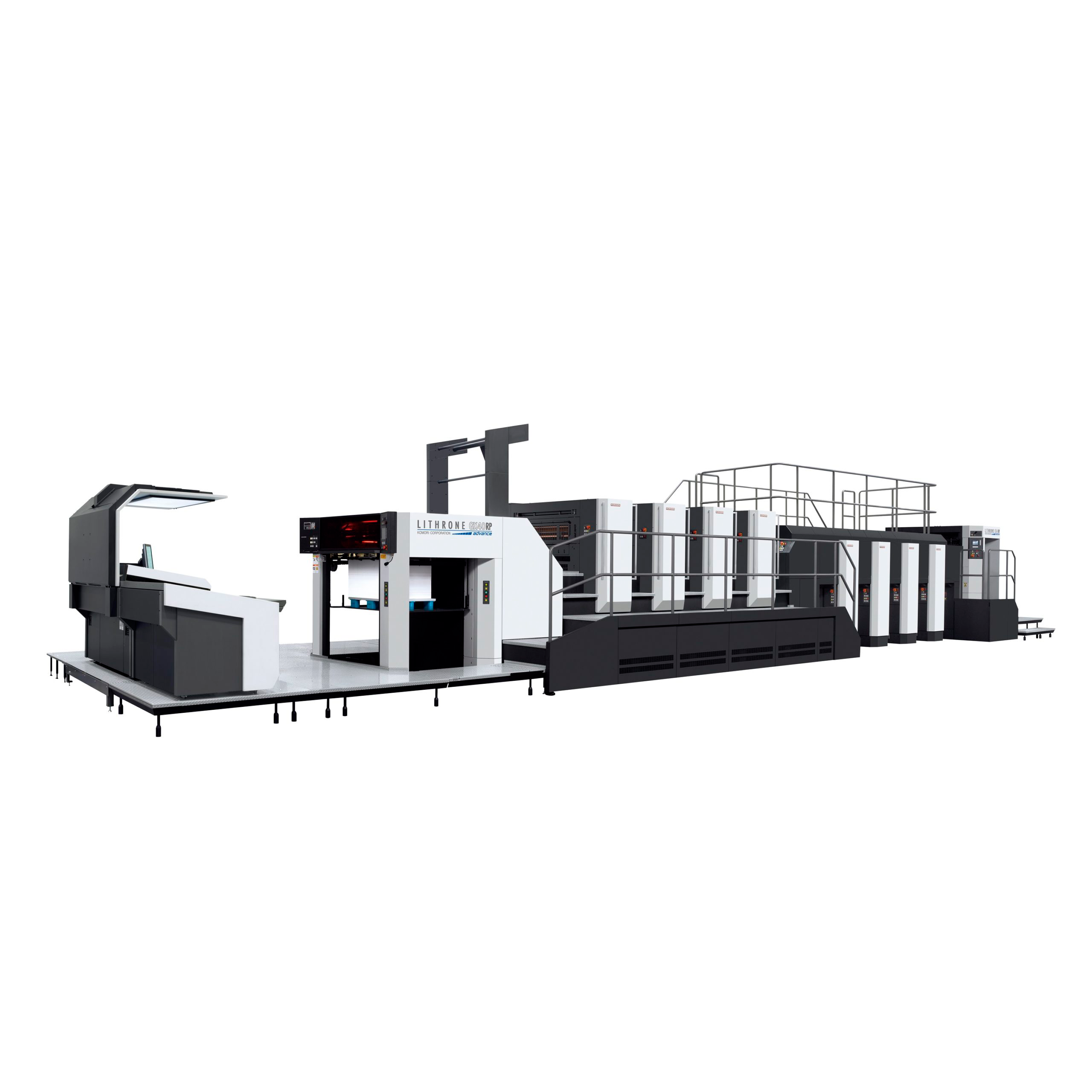

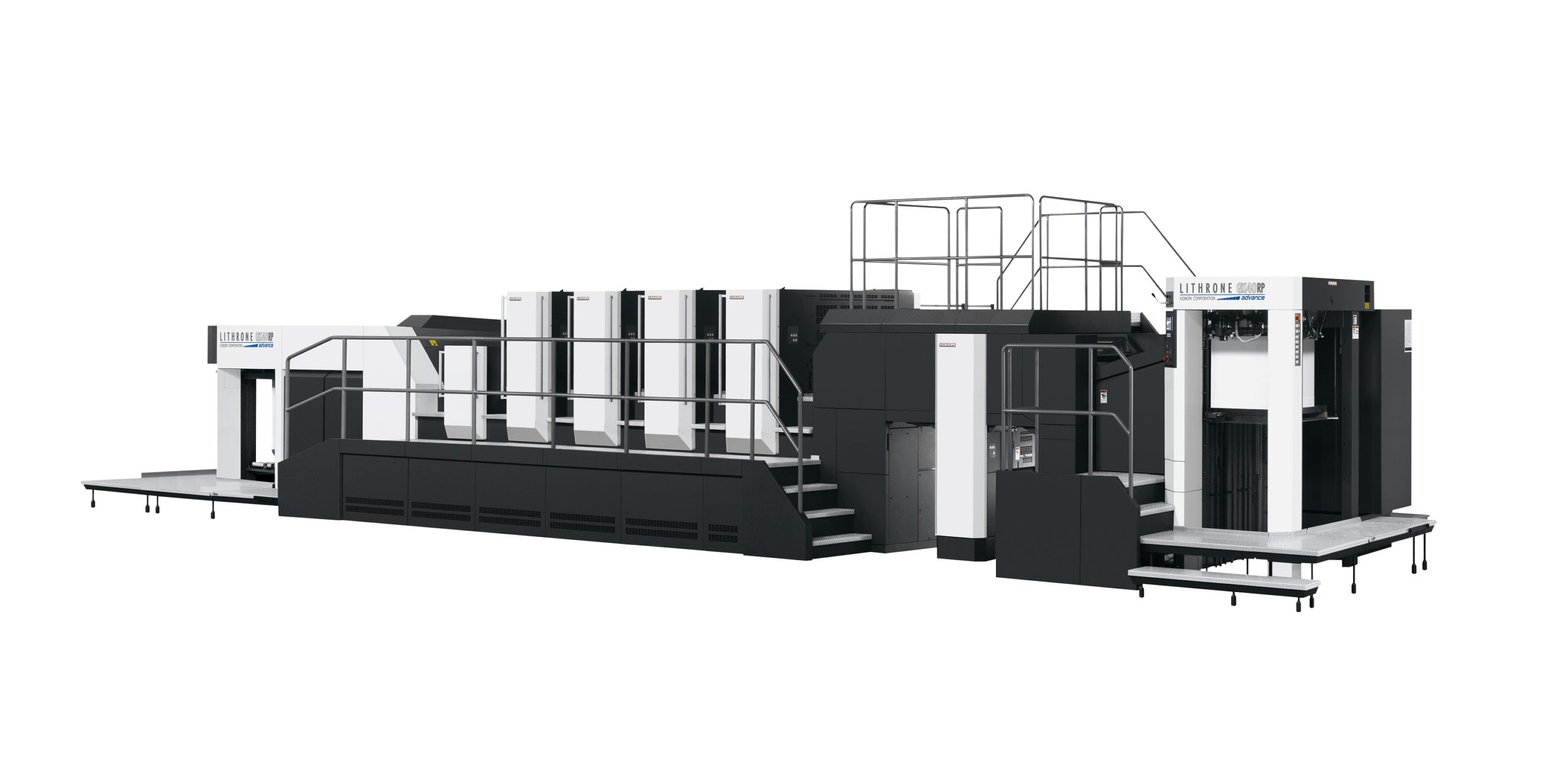

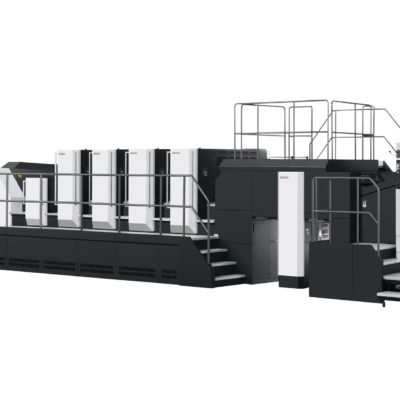

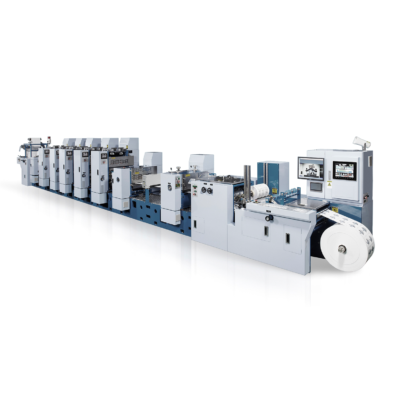

This machine expands the OffsetOnDemand range thanks to its fast set-up and instant drying without anti-scaling powders, allowing you to handle very small batches and short deliveries thanks to the integrated KHS-AI start control system and the H-curing system UV. The maximum print speed is 18,000 sheets per hour. It can be configured to accept thin sheets for commercial printing and cardboard for packaging printing.

In addition, this machine can be equipped with the A-APC asynchronous automatic plate changing system, the PDC-SX spectral density control, and the PQA-S print quality evaluation system for cut sheets, with the aim of achieve even higher levels of quality and productivity.

The Lithrone GX40RP combines know-how and innovative technologies to achieve high automation, standardization and innovation. An advanced platform for a new generation of printers.