Characteristics

Stunning effects

Applies UV spot varnish and hot foil to coated and uncoated materials, synthetics, paper, and lightweight cardboard

Easy to use

Quick-to-understand, easy-to-use equipment requiring fewer special skills, freeing up operators to do other jobs

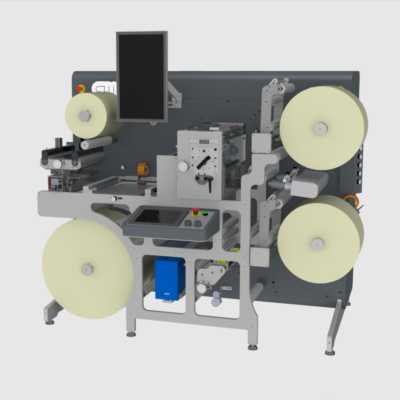

Flexo UV rotary complete station

In-line rotary Flexo UV station, for deep varnishing, allows UV varnishing and hot foil finishing on a wide variety of substrates, including uncoated materials

IFoil technology, hot stamping 100% digital

Digital / variable embellishments of varnish and 2D and 3D lamination, added value for self-adhesive labels and flexible packaging, being able to choose between metallic, holographic and colored lamination.

MGI Artificial Intelligence Smartscanner (AIS) or scanner with Artificial Intelligence

The varnish and hot sheet registration system automatically scans each sheet and compares it to the digital mask; no registration marks, reducing make-ready times and waste

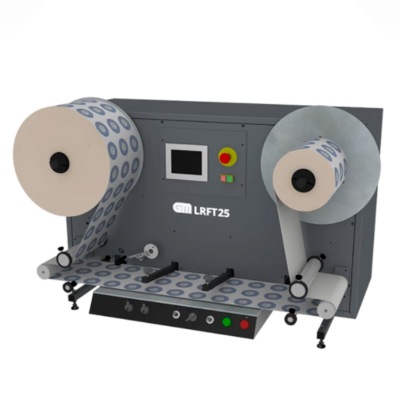

Unwinder and rewinder

Variable grid width, automatic coil diameter calculation, tension setting division table and more

High production speed and perfect varnish quality

Speeds up to 42 meters per minute, 7 to 232 micron touch and styling effect

Wide compatibility

Compatible with digital, flexo and offset web-to-web printing technologies

Technical specifications

Production speed

Up to 42 m / min (depending on printing parameters)

Bandwidth

From 100mm to 420mm

Finish width

The maximum image width is 405mm

Supported media types

From 50 to 400 microns (µm)

Coated, uncoated paper, film

Self-adhesive labels

White or transparent synthetic substrate (PP, PE, POPP, PET)

PVC, PETG

Lightweight / folding carton

Wide compatibility

Compatible with all web-to-roll printing technologies. Narrow web digital machines and traditional narrow web offset or flexo presses.

Unwinder

- Maximum coil diameter 850 mm

- Standard inside diameter 3 inches

- Maximum coil weight approx 120 kg

Flexo UV Station

An integrated flexo station for rotary full-size coating. This station is used to apply a UV protection varnish or a primer before finishing. The module comes with a UV dryer.

The station is equipped with an anilox cylinder.

UV coating station

This station uses the award-winning MGI ink injection technology to produce a UV varnish coating. Any defined label area can be UV coated with or without 3D effects.

A simple prepress engineered grayscale TIFF file controls the surface area and thickness of the varnish applied on the printed roll. This 100% digital process eliminates traditional plates, screen and dies.

Varnish thicknesses

From 7 to 232 microns of varnish thickness (from 2D varnishes to 3D varnish effects).

In-line drying

The station is equipped with a UV dryer and a cooler for optimal control of the temperature of the paper web. The curing sequence also includes a special back and forth motion to dry each label and eliminate waste between runs.

Hot Foil Unit

The hot laminating station adds special effects and brand value to labeling and packaging products. Any defined label area can receive a digitally controlled foil with or without 3D effects.

A simple prepress engineered grayscale TIFF file controls the surface area and thickness of the varnish applied on the printed roll. This 100% digital process eliminates traditional plates, screen and dies.

The application of the foil can be omitted when not necessary.

Foil Coils

Foil coil width from 100 mm to 420 mm.

Foil coil length from 400m to 2000m.

Up to three simultaneous foil reels

Die unit

A semi-rotary die cutting unit is available as an option for finishing labels in line on the JETVARNISH 3DW machine.

The unit uses a 21 ″ magnetic cylinder and an automatic registration system. 2 cutter blades and a die rewinder included

- Semi-rotary format from 100 to 420 mm

- Maximum diameter of the die 600 mm

- 2 blades as standard

- Gapmaster system for height adjustment as optional

Rewinder

Servo-motorized unit

Maximum coil diameter 850 mm

Maximum coil weight 120 kg approx

Variable data finishing system

· Manage and edit files on the workstation

Full variable data for 2D / 3D varnishing areas and hot rolling areas

Integrated barcode reader system

RIP as optional

Other options

Corona treatment. Online system that optimizes the adhesion of varnish on complex substrates.

JETvarnish 3DW Dimensions and Weight

11.85 x 1.58 x 1.83 meters approx (LxWxH)

Clearance: 1 meter (3.3 feet) on 4 sides

+ - 4447 kg approx

Electrical requirements

40 kW (63A) at 400 volts - 50/60 Hz

20 kW (32A) at 400 volts - 50/60 Hz

(1) Print speed will vary depending on the printing parameters used (format, weight, paper conditions).

• Some product illustrations may include optional accessories.

• Specifications and accessories are based on information available at the time of publication and are subject to change without notice.

• OMC, SAE does not guarantee that the specifications mentioned are error-free.