Technical Specifications - Varnishing

UV inkjet technology

• MGI’s exclusive inkjet engine technology.

• Drop-on-demand (Dod) inkjet application.

• Single-pass piezoelectric print heads.

• Flexible and scalable architecture.

Variable varnish thicknesses

Depending on the file and media used, the thickness of the coating can vary from the traditional flat UV mode of 3 to 200 microns to achieve an embossed 3D effect and a tactile finish.

Production speed

Up to 3000 (1) B2 sheets per hour approx in all versions, with 18 micron varnish effect.

Registry

Lateral registration guides motorized on the right and left. Automatic registration through a built-in scanner for real-time management of the entire sheet. No registration marks are required.

Supported paper formats

Min: 420 × 297mm / 8 × 11.8 '' (width by height)

Max .: 52 × 120cm / 20 × 47 '' (standard)

75 × 120 cm / 29 × 47 '' (3)

Width of print areas

51 cm / 20 '' (standard)

63 cm / 24.8 '' (3)

74 cm / 29 '' (3)

Media thickness

• Motorized inkjet head height adjustment.

• Min.: 135 gsm and not less than 150 m / 6 mil before printing and laminating.

• Max: 600 gsm and no more than 600 m / 24 mil before printing and laminating.

Media compatibility

Improvement on most (4) laminated matte or glossy surfaces, with or without aqueous varnish, laminated paper, plastic, PVC and other varnished materials. 3D reserve varnishing directly on most (4) digital impressions (for example: MGI Meteor).

UV varnishing and performance

Several coating formulas available, one designed for 2D (flat coating) and one for 2D / 3D use. The JETvarnish 3D Evo includes 2 reservoirs and 2 varnish circuits as standard that allow quick changeover between varnish types. Both tanks have a large capacity (18 liters / 4.7 gallons). Instant tank change is possible during production without interruptions or waste.

75 cm sheet feeder

High capacity feeder capable of stacking paper up to 60cm / 23.6 '' high for 75 × 120cm (29 × 47 '') sheets. Approximately 4000 sheets at 135gsm.

75cm pallet stacker

Holds sheets up to 75 × 120cm (29 × 47 '') in size in pallet packaging.

Paper path

• Paper path 100% flat.

• Air suction system.

• Air emission system.

• Automatic double-fold detection.

Inline UV Dryer

Instant drying and curing through built-in UV lights.

Front End System

• Intuitive touchscreen management software controlled via a 27'' monitor.

• Functions for operators:

• Job cost calculator, image editor, queue and reprint management, camera and printhead settings.

• Controller of equipment configuration and technical data.

• 10/100/1000 BT Ethernet connection on RJ 45.

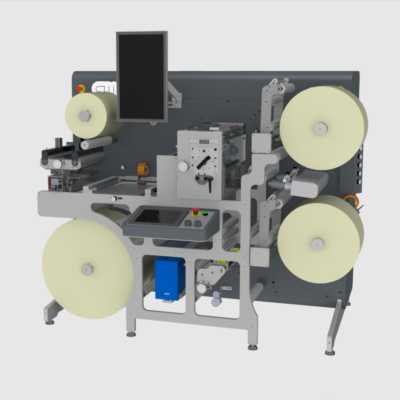

Technical Specifications - Hotfoil

iFOIL L

Application of the optional 100% digital hot stamping module. Standard sheet format 75 × 120 cm (29 × 47 '').

Production speed

Up to 1200 (5) B2 sheets per hour approx (or up to 25m per minute approx - 65.6 feet per minute approx).

Films

Uses a variety (6) of commercially available hot foils. Film consumption optimization system.

Coils

Max diameter and length: + -30cm / 11.8 '' and from 400 to 2000 meters of film (1300 to 6500 feet).

Up to 5 simultaneous coils on the same axis (with a minimum of 10cm / 3.9 '' per coil)

2 cores available: 1 inch as standard and 3 inch optional.

Maximum surface

The hot rolled surface cannot exceed 74 × 119 cm (29.1 × 46.8 '').

Print

18 to 200 m thick. The surface of the metallized film can be covered with a layer of lacquer or other foil.

Dry air

Requires oil-free air at a supply of 6 bar (87 psi) & 24 m3/h.

Other options

64cm Upgrade Upgrade Kit Evo:

Upgrade or later option for printing sheets up to 64 × 120 cm / 24 × 47 '' in size.

75cm Upgrade Upgrade Kit Evo:

Upgrade or later option for printing sheets up to 75 × 120 cm / 29 × 47 '' in size.

Variable Data Enhancement (VDE)

The instantaneous variable data optical system uses a camera and pre-printed barcodes. Variable data for text, graphics and images both in areas with 2D / 3D Reserve varnish and in hot rolled areas.

Maintenance and Remote Technical Assistance

• New: Automated inkjet head cleaning and drying.

• Complete daily maintenance in less than 10 min.

• Most automated processes.

• Go from cold start to production in less than 15 min.

• Remote assistance and troubleshooting via included webcam (requires high-speed internet connection).

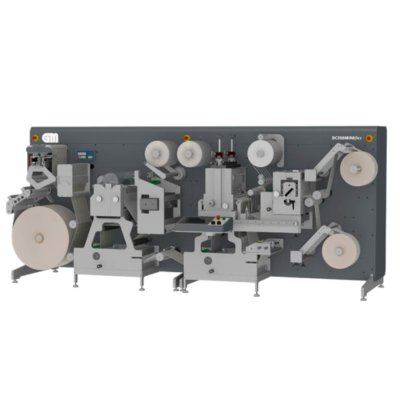

JETvarnish 3D EVO + iFOIL Dimensions and Weight

11.10 x 1.96 x 1.83 meters (LxWxH)

Clarification: 1 meter on 3 sides and 2 meters on the side of the stacker.

± 5000 kg

Electrical requirements

JETvarnish 3D Evo + iFOIL L

40 kW (63A) at 400 volts - 50/60 Hz

20 kW (32A) at 400 volts - 50/60 Hz

Operating environment

Temperature: 18 to 30ºC / 64 to 86ºF

Relative humidity between 30 and 50%. (No condensation).

The default sheet size is B2 (52x74cm / 20 × 29 '') unless otherwise noted.

(1) The speed will vary depending on the printing parameter used.

(2) with the 75cm / 29 '' Evo kit.

(3) depending on the options chosen.

(4) confirm support / toner / metallic film compatibility with MGI.

(5) the speed will vary depending on the printing parameter used.

(6) confirm support / toner / metallic film compatibility with MGI.

• Some product illustrations may include optional accessories.

• Specifications and accessories are based on information available at the time of publication and are subject to change without notice.

• OMC, SAE does not guarantee that the specifications mentioned are error-free.