Since its launch, in the middle of the last century, Orvy ha evolved from the publishing sector to the printing sector, accumulating more than 50 years of experience in guaranteeing the best graphic services to its clients, who enjoy the total commitment of the human team of this company located in Hernani. The constancy in a sensible innovation, continuous training and vocation cause a high loyalty by those who use their services.

We have had the invaluable opportunity to visit the facilities of Orvy Graphic Printing, which has 1,800 m2 perfectly air-conditioned, with temperature and humidity control to guarantee optimal storage and production conditions, where we were attended by the brothers Paco and Joseba Beloki, owners of the company, components of the second generation in charge of this project business "that our father, José Manuel Beloki, started at a time when typography still worked", Comments Paco Beloki,"and since then we have evolved in various locations, incorporating the offset printing in 35 x 50 cm format, in one, two four colors until incorporating the first CtP systems Starting in 2000, we later expanded the format to the 70 x 100 print and recently we bet on the H-UV printing technology, in five colors plus varnish".

We have had the invaluable opportunity to visit the facilities of Orvy Graphic Printing, which has 1,800 m2 perfectly air-conditioned, with temperature and humidity control to guarantee optimal storage and production conditions, where we were attended by the brothers Paco and Joseba Beloki, owners of the company, components of the second generation in charge of this project business "that our father, José Manuel Beloki, started at a time when typography still worked", Comments Paco Beloki,"and since then we have evolved in various locations, incorporating the offset printing in 35 x 50 cm format, in one, two four colors until incorporating the first CtP systems Starting in 2000, we later expanded the format to the 70 x 100 print and recently we bet on the H-UV printing technology, in five colors plus varnish".

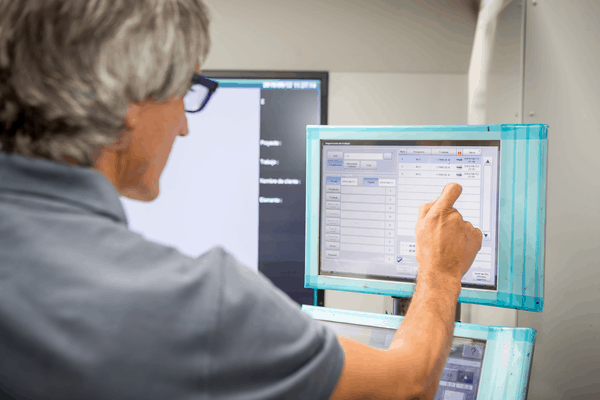

Currently, Orvy Graphic Printing has a machinery park made up of 15 printing units, among which are those in the 75 x 105 cm format, used to provide service and a widely personalized response to those who demand quality graphic product. Not in vain, its human team constantly strives for professional advice to the client, with the possibility of assisting the process at the machine, maintaining a control system for all processes and adjusting to the increasingly reduced delivery times that it demands. the market.

Diversifying the commercial graphic product

"Our main areas of action", Explains Joseba Beloki,"They are usually commercial work, publishing, magazines, brochures and also posters or some packaging ... we are in a position to provide a very diversified service and we have our own die-cutting to attend small runs of folders, brochures, etc."Their clients come, as is to be expected, from their immediate surroundings in the area where they operate, but thanks to the 'word of mouth' the positive assessment of their actions has spread and currently"we have a client in the Basque-French area, also in Paris", Says Joseba Beloki,"and all this with almost no commercial structure, functions that my brother and I usually assume".

Currently, Orvy Graphic Printing has a machinery park made up of 15 printing units, among which are those in the 75 x 105 cm format, used to provide service and a widely personalized response to those who demand quality graphic product. Not in vain, its human team constantly strives for professional advice to the client, with the possibility of assisting the process at the machine, maintaining a control system for all processes and adjusting to the increasingly reduced delivery times that it demands. the market.

Diversifying the commercial graphic product

"Our main areas of action", Explains Joseba Beloki,"They are usually commercial work, publishing, magazines, brochures and also posters or some packaging ... we are in a position to provide a very diversified service and we have our own die-cutting to attend small runs of folders, brochures, etc."Their clients come, as is to be expected, from their immediate surroundings in the area where they operate, but thanks to the 'word of mouth' the positive assessment of their actions has spread and currently"we have a client in the Basque-French area, also in Paris", Says Joseba Beloki,"and all this with almost no commercial structure, functions that my brother and I usually assume".

Sometimes, indeed, rather than an invasive communication activity or aggressive commercial performance, it is better to let the very excellence of the professional performance of the Orvy team spread the values of trust, discretion and respect by the wishes of customers. Some clients who usually go to this graphic company to have the peace of mind of a supplier that conscientiously respects their work, with total confidence.

Innovation, added value and adaptation to the market

"Since its creation", Says Paco Beloki,"Following in the footsteps of our father, at Orvy we have strived to continually consolidate and improve services to our customers, always investing in the latest printing and finishing technologies.".

Sometimes, indeed, rather than an invasive communication activity or aggressive commercial performance, it is better to let the very excellence of the professional performance of the Orvy team spread the values of trust, discretion and respect by the wishes of customers. Some clients who usually go to this graphic company to have the peace of mind of a supplier that conscientiously respects their work, with total confidence.

Innovation, added value and adaptation to the market

"Since its creation", Says Paco Beloki,"Following in the footsteps of our father, at Orvy we have strived to continually consolidate and improve services to our customers, always investing in the latest printing and finishing technologies.".

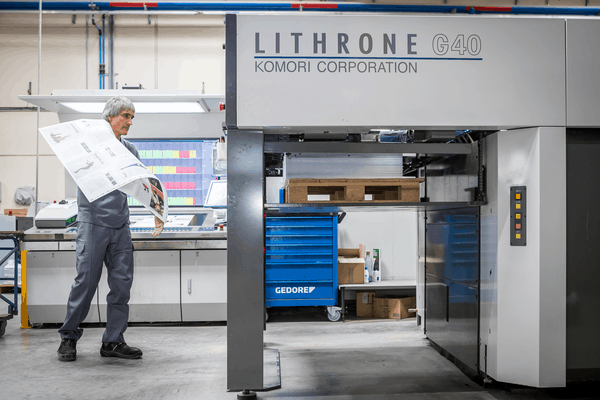

Orvy Graphic Printing has the aforementioned section of offset printing, but also provides digital printing service for all types of products in short runs that require immediacy, solving emergencies or customization. To this must be added the ability to give extraordinary added value with a excellently equipped finishing phase with the possibility of applying machine varnish, also UVI, plasticizing, stamping, punching, fingernails, holograms or odorants. Precisely, this continuous reinvestment philosophy, added to the professional expertise of a team in constant training to perfect their skills and abilities in the graphic industry sector, has motivated Orvy's bet by one of the latest technologies with the greatest projection in the world of offset: the impression H-UV from Komori, materialized in a press Komori Lithrone G40.

Orvy Graphic Printing has the aforementioned section of offset printing, but also provides digital printing service for all types of products in short runs that require immediacy, solving emergencies or customization. To this must be added the ability to give extraordinary added value with a excellently equipped finishing phase with the possibility of applying machine varnish, also UVI, plasticizing, stamping, punching, fingernails, holograms or odorants. Precisely, this continuous reinvestment philosophy, added to the professional expertise of a team in constant training to perfect their skills and abilities in the graphic industry sector, has motivated Orvy's bet by one of the latest technologies with the greatest projection in the world of offset: the impression H-UV from Komori, materialized in a press Komori Lithrone G40.

"And we have noticed a lot the advances in issues such as the reduction of job preparation", Explains Paco Beloki,"with sensible improvements to face smaller and smaller runs". "Although in reality", Adds Joseba Beloki,"In large print runs, from our point of view, conventional offset remains competitive. Our average print runs are usually two to three thousand copies, in shifts of between thirteen and fourteen hours that involve about twenty or twenty-five changes ... although we could get to assume production with almost 18 changes in eight-hour shifts, but not for runs. more than 800 copies, for example".

Improvements and advances with H-UV technology

Apart from the improvement in print quality, "what we have noticed the most printing with H-UV is the process cleanliness", Explains Joseba Beloki,"no antimaculating powders, scratched… Something that is greatly appreciated in the subsequent process. Entering the jobs in the folder has been an important advance, because the rollers do not stain ink ... when using conventional offset, with prints with a lot of ink, even if you wait a day, then many problems are generated in the folding. Now we print, and after a few minutes we can fold without problems. However, as I said before, all this is very convenient in medium-small types of runs, but with runs of more than one hundred or three hundred thousand copies the profitability with conventional offset printing remains competitive, since the inks are cheaper".

"And we have noticed a lot the advances in issues such as the reduction of job preparation", Explains Paco Beloki,"with sensible improvements to face smaller and smaller runs". "Although in reality", Adds Joseba Beloki,"In large print runs, from our point of view, conventional offset remains competitive. Our average print runs are usually two to three thousand copies, in shifts of between thirteen and fourteen hours that involve about twenty or twenty-five changes ... although we could get to assume production with almost 18 changes in eight-hour shifts, but not for runs. more than 800 copies, for example".

Improvements and advances with H-UV technology

Apart from the improvement in print quality, "what we have noticed the most printing with H-UV is the process cleanliness", Explains Joseba Beloki,"no antimaculating powders, scratched… Something that is greatly appreciated in the subsequent process. Entering the jobs in the folder has been an important advance, because the rollers do not stain ink ... when using conventional offset, with prints with a lot of ink, even if you wait a day, then many problems are generated in the folding. Now we print, and after a few minutes we can fold without problems. However, as I said before, all this is very convenient in medium-small types of runs, but with runs of more than one hundred or three hundred thousand copies the profitability with conventional offset printing remains competitive, since the inks are cheaper".

"But there is no doubt", Says Paco Beloki,"that the extra cost of the H-UV ink can be compensated with the saving in spots, which is considerable. It is printed, and since it is not necessary to use antimaculante powder, jobs with turning, or strip-removal in small runs, with high grammage or with a lot of ink are not a problem". Also, the H-UV technology, a system that uses curable inks with H-UV / LED light using high sensitivity lamps, in addition to providing shorter print times, a instant drying without risk of repainting and special graphic effects using specific varnishes, expands the range of usable media, such as plastic supports.

"But there is no doubt", Says Paco Beloki,"that the extra cost of the H-UV ink can be compensated with the saving in spots, which is considerable. It is printed, and since it is not necessary to use antimaculante powder, jobs with turning, or strip-removal in small runs, with high grammage or with a lot of ink are not a problem". Also, the H-UV technology, a system that uses curable inks with H-UV / LED light using high sensitivity lamps, in addition to providing shorter print times, a instant drying without risk of repainting and special graphic effects using specific varnishes, expands the range of usable media, such as plastic supports.

"Thanks to the progressive experience that we are acquiring in H-UV technology", Says Joseba Beloki,"There are products and specialties that we are incorporating with less fear. We had some problems in materials that we were not aware of, such as plastic, which we must select so that it remains in optimal conditions for printing, or the problems that can be generated if the maintenance and / or replacement of the UV drying lamps is neglected according to the specified working hours ". "Some of the problems we experience", adds Paco Beloki, “They happened because of our inexperience in new materials, but we don't want to stay here, we just want add more types of products, with greater added value mixing conventional varnishes with UV, with which very spectacular special effects are achieved".

The added value guarantees the future

Thanks to that enhancement of added value in the same printing phase, which enables a new universe of finishes and effects, "we can firmly get out of the usual price struggle in the supply of graphic and printed product", Says Joseba Beloki,"something from which we, maintaining a firm seriousness and commitment to the requirements of our clients, have traditionally fled. If you struggle to lower the price, you are stagnating, because even if you already have the machine amortized, you need to continue investing in new technologies. The client accepts a correct cost if you offer a quality service, with added value and you maintain strict seriousness in delivery times, that you trust that there will be no incidents in your order".

"Thanks to the progressive experience that we are acquiring in H-UV technology", Says Joseba Beloki,"There are products and specialties that we are incorporating with less fear. We had some problems in materials that we were not aware of, such as plastic, which we must select so that it remains in optimal conditions for printing, or the problems that can be generated if the maintenance and / or replacement of the UV drying lamps is neglected according to the specified working hours ". "Some of the problems we experience", adds Paco Beloki, “They happened because of our inexperience in new materials, but we don't want to stay here, we just want add more types of products, with greater added value mixing conventional varnishes with UV, with which very spectacular special effects are achieved".

The added value guarantees the future

Thanks to that enhancement of added value in the same printing phase, which enables a new universe of finishes and effects, "we can firmly get out of the usual price struggle in the supply of graphic and printed product", Says Joseba Beloki,"something from which we, maintaining a firm seriousness and commitment to the requirements of our clients, have traditionally fled. If you struggle to lower the price, you are stagnating, because even if you already have the machine amortized, you need to continue investing in new technologies. The client accepts a correct cost if you offer a quality service, with added value and you maintain strict seriousness in delivery times, that you trust that there will be no incidents in your order".

Apart from all these advantages that the Beloki brothers tell us about the implantation of the Komori H-UV technology, one of the factors that influenced this decision is the importance that they have always given to the after-sales service and to manufacturer and distributor technical support. "It's something our father already taught us", Says Joseba Beloki,"When making decisions, it must be done in a very studied way, as we did at the time of incorporating CtP technology, analyzing all technologies, options and manufacturers, but taking into account the factor of trust and solvency of the person who is going to supply us with the equipment or the solution, because sometimes the technical service is not provided by the seller but is a third party. In this case, apart from the natural incidents that always happen, we are very satisfied with the support you have given us. WTO". As we can see, after an unfortunate period of crisis, in which the graphic industrial fabric has suffered greatly, the Business even of family character that remain they always do with him vocational commitment for their work, the maintenance of a philosophy facing a constant reinvestment in innovation and one reinvention of the range of services they offer to an increasingly competitive market, but what has not neglected the values of personal treatment, trust and complete guarantee in all phases of graphic production.

Apart from all these advantages that the Beloki brothers tell us about the implantation of the Komori H-UV technology, one of the factors that influenced this decision is the importance that they have always given to the after-sales service and to manufacturer and distributor technical support. "It's something our father already taught us", Says Joseba Beloki,"When making decisions, it must be done in a very studied way, as we did at the time of incorporating CtP technology, analyzing all technologies, options and manufacturers, but taking into account the factor of trust and solvency of the person who is going to supply us with the equipment or the solution, because sometimes the technical service is not provided by the seller but is a third party. In this case, apart from the natural incidents that always happen, we are very satisfied with the support you have given us. WTO". As we can see, after an unfortunate period of crisis, in which the graphic industrial fabric has suffered greatly, the Business even of family character that remain they always do with him vocational commitment for their work, the maintenance of a philosophy facing a constant reinvestment in innovation and one reinvention of the range of services they offer to an increasingly competitive market, but what has not neglected the values of personal treatment, trust and complete guarantee in all phases of graphic production.