FlexoMatrix is a smart technology platform that automates the flexo plate mounting and facilitates job management for the operator.

It is designed for any operator to mount plates reliably, with maximum uniformity and precision.

Your ability to 360 ° print registration speeds up set-up times in the workshop, something that in today's market with fixed color palettes and increased short runs represents significant cost savings.

Lars Lehner, CEO Lehner GmbH, explains how your digital technology FlexoMatrix help to improve flexo plate management automating it and giving it much greater flexibility in its subsequent printing process in flexography.

What was the starting point for the development of FlexoMatrix technology?

It is well known that, in recent years, the level of training in the sector has decreased, while price pressure and short runs have not stopped increasing with increasing competition.

There was a clear need to improve automation and precision of printing processes, and the mounting and handling of flexo plates was an area that had long been ignored.

Our goal was to link data management with the production process through a practical tool that was reliable and easy to use. That is why we developed a new technology platform to which we have called FlexoMatrix.

How does it work and what are its advantages?

In essence, FlexoMatrix is a digital technology platform what automates plate mounting and facilitates job management for the operator.

It is designed so that even less knowledgeable operators can mount plates reliably, with maximum uniformity and precision.

His 360 ° print logging capability speeds up set-up times in the workshop, something that in today's market for fixed color palettes and short runs represents significant cost savings.

Does FlexoMatrix have a universal application?

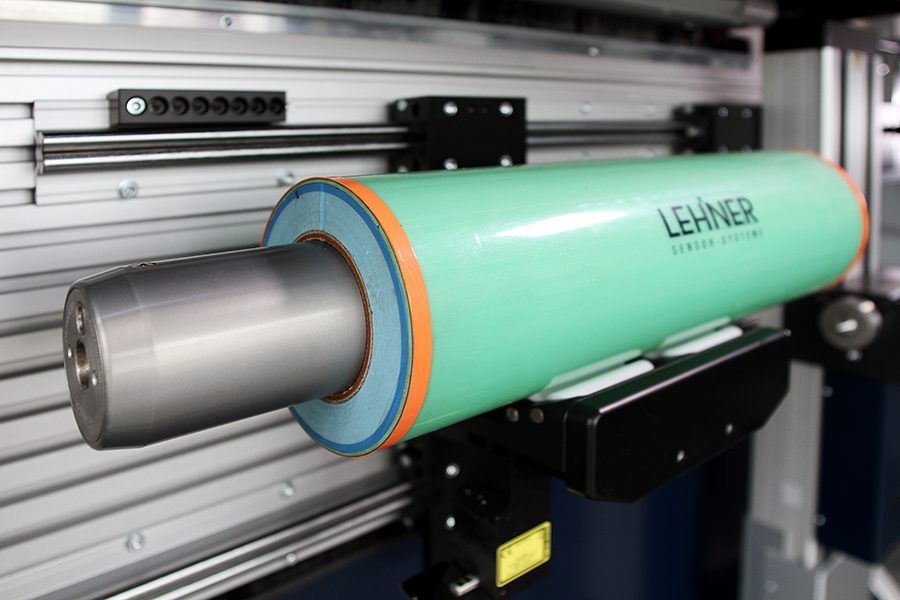

When it comes to flexibility, yes. A quick-change adapter system allows it to handle most sleeves and cylinders, making it a comprehensive tool for all forms of flexo prepress, From Ccorrugated cardboard to cardboard boxes, flexible packaging and labels.

It is compatible with all major plate brands, including Asahi and Kodak, as well as most sleeves and cylinders.

How do you manage production data?

Act like digital bridge between existing job management, prepress area and print shop.

Through a individualized counseling With the customer, we can adapt FlexoMatrix to each job management system, thereby saving time by not having to manually enter data about the job such as run length, cylinder type, direction, etc.

Are we only talking about an acceleration process?

No too adds a layer of security to the productBecause each plate is identified before mounting and the printing direction is checked. In this way, the problems derived from the mixing of plates disappear.

It also brings a new degree of transparency to job planning, optimizing production.

Thanks to this, it is possible to better plan shift patterns, as well as to more easily identify the reasons for cost overruns and deadlines being exceeded.

How does FlexoMatrix identify plates?

Is based on the ID using smart disks, making it easy to archive used plates.

For example, in those situations where an operator would have had difficulty reading the text written on the plates and would not have known how or where to file them, the FlexoMatrix identification system makes it an automatic process and eliminates another variable from the production chain .

What are the consequences?

Since FlexoMatrix knows which plate is mounted on which sleeve or cylinder, reduces the risk of errors and provides traceability.

Information on the "yield" of the plate and its location can be obtained with additional scanning technology in the printing press and in the plate archive.

What else does it offer?

Provides useful information to the job management system, As the plate and cylinder number, the accuracy of the mounting process, the printing direction in which the plate was mounted, and a timestamp.

In this way, new data is obtained that makes planning and job management more efficient.

The result is greater process efficiency and lower costs, which translate into higher margins.

How would you summarize the benefits for someone considering purchasing FlexoMatrix?

The improvements it brings are evident at different levels.

First of all, we have better record quality in 360º and greater record transparency in all flexographic printing processes of the plant. Thanks to this, reduces material waste in job changes, so the printing machines can print more jobs.

On the other hand, results obtained establish a new reference for subsequent work and repetitions, which allows the company to optimize its productive efficiency. Typical registration problems become a thing of the past and printers win standardization and independence of operators.

For these companies, FlexoMatrix allows them to take an easy and crucial step into the future of flexographic production.

Do the benefits vary based on the size of the company?

Yes, because each company is different and has its own problems and priorities.

For the larger printers, FlexoMatrix Act like a comprehensive and extremely reliable technology platform that uses your existing data management to improve automation and transparency in your workflows.

Smaller companies like it because they helps streamline your current processes and allows you to focus on producing a higher volume of high-quality prints with all your flexo equipment.

Regardless of the size of the company, tAll benefit from greater operator independence and FlexoMatrix's 360º controlled assembly process, which offers the highest precision on the market. Everywhere you look, it is a 'win-win'.