The NEO Group It is among the most important European companies in post-printing and finishing services for Graphic Arts and Packaging.

Founded in 1989 with the creation of what is now NEOPlastif, NEO Group has grown to add the divisions that currently comprise it: NEOPlastif, NEOFolder, NEOBarniz, and NEOStamp.

The group offers laminating services, UV varnishing (offset, screen printing and digital), thermal stamping, die-cutting, dry stamping, folding and gluing.

The harshness of the economic situation is evident in the recent evolution of the NEO Group. Changes in the market and the tremendous reduction in activity as a consequence of the general crisis have led to the reorganization of capacities and to scale them with the closure of several production centers. "Now we have the resources concentrated in the Parla plant, south of Madrid", indicates Raúl García Magán, CEO of Grupo NEO. "We are at the turnover levels of fifteen years ago, but the future is so uncertain that it makes it impossible to make any estimate for next year."

“Our type of business is based on the proximity with our client, the printer. It is a service model that is very difficult to internationalize, so we have to focus on the closest market ", says Raúl García Magán. "That is why we believe that a change in mentality is necessary, go one step further, and be able to serve our customers with a unique solution that goes beyond conventional UV varnishing."

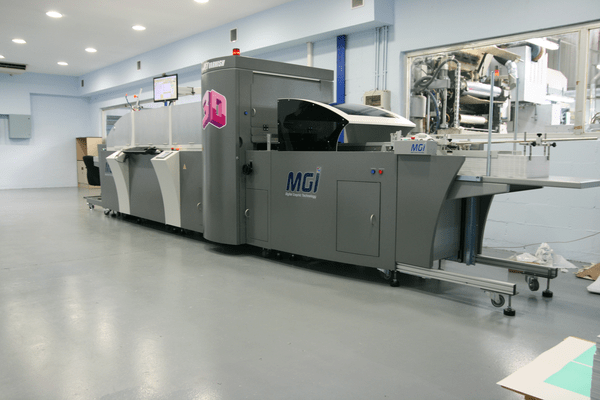

After five years, in which the Group has been absent from its usual investment activity to update capacities, they have incorporated a MGI Jetvarnish 3D UV inkjet digital coater.

"For two Drupas we had our sights set on different options for digital finishes", explains Raúl García Magán. “In 2008 the MGI Jetvarnish 3D still did not offer the performance we were looking for. However, in 2012 the team already met our expectations ”.

“It was at Graphispag Digital 2013 where we officially presented and launched the new Jetvarnish 3D nationwide. During the Fair we were able to verify "in-situ" the excellent acceptance and interest generated by its combined 2D and 3D finish in a single pass. Many were the printers, graphic designers ... who asked us where to order or carry out high-value-added finishes such as those seen in the different demonstrations carried out during the event " comments Michel Madoz, Marketing Director of OMC, sae.

“It was surprising to see how selective UV varnishing with relief, combining 2D and 3D, generates and causes incredible interactivity between the finished print and the end consumer. The extra or added value that this equipment brings to printed material could be reduced in a single word; Temptation. Generates that "irresistible" impulse to touch it, interact with it and discover new sensations " Michel Madoz remarks.

"Once we determined the purchase of the MGI Jetvarnish 3D the next stumbling block was finding financing", laments Raúl García Magán. “There are entities that, directly, neither attend you, nor study the operation, because they have orders to leave the graphic sector. In the end, after three months and knocking on many doors, we got the necessary financing with the guarantee of Avalmadrid, whom we have to thank for continuing to collaborate with us ”.

MGI's Jetvarnish 3D UV inkjet coater, distributed in Spain by OMC, sae; It allows you to fully customize UV varnishing both in the usual 2D applications and in the new and spectacular 3D application that adds relief to printed materials, providing an aesthetic and sensorial ennobling.

“To impact, captivate, surprise, be remembered, attract attention… these are the most valued objectives for any printed piece (container, magazine advertisement, catalog, packaging…). Thanks to the 3D selective UV varnishing, a new level of demand or expectations is reached " Michel Madoz comments.

“To impact, captivate, surprise, be remembered, attract attention… these are the most valued objectives for any printed piece (container, magazine advertisement, catalog, packaging…). Thanks to the 3D selective UV varnishing, a new level of demand or expectations is reached " Michel Madoz comments.

The equipment is designed to be integrated into a finished environment for printed products, both with digital and offset technology, in sheet sizes up to 52 x 105 cm. "In short and ultra-short runs, MGI's Jetvarnish 3D allows UV varnishing to be applied at very competitive costs", says Enrique Rodriguez García, Director General of OMC, sae.

MGI's Jetvarnish 3D uses piezoinkjet technology heads that cover the entire width of the sheet in a single pass in thicknesses ranging from 3 to 200 microns, in the case of 3D finishing. The equipment is capable of varnishing up to 3,000 B2 sheets per hour, in 2D finishing mode. "We considered other options on the market, but they lacked the industrial robustness that continuous cycle production requires", says Raúl García Magán.

"The incorporation of this team has been a challenge for us in terms of training, since it requires knowledge of prepress that with the rest of our finishing processes was not necessary", says Raúl García Magán. "The operators of the MGI Jetvarnish3D have received specific prepress training at the Tajamar Technological and Graphic Institute".

MGI's Jetvarnish 3D is going to be integrated, within Grupo NEO, in a hybrid production environment where the finishing options available to the company will be combined with the new possibilities that this digital equipment allows.

"On NEO Group We have always been at the forefront in terms of services and technologies. We felt the need to get back in the position to write our destiny and offer something different and attractive to our clients ”, says Raúl García Magán. "With the MGI Jetvarnish 3D we will be able to bring something fresh, striking and special to printers who seek to distinguish their production".