It is very comforting to see that firms from the Vanguard Gràfic experience, throughout its more than one hundred years of history, have never stopped innovating and maintaining the passion and love that they have professed for their work, for five generations. Thinking long-term never prevents the continuous effort to have the latest technology at the service of its customers, in this case the H-UV offset technology developed by Komori.

In an industry as traditional as graphics, it is paradoxical that the best firms dedicated to this world are those that focus the most on innovation. This is the case of Vanguard Gràfic, which throughout its long history, which has seen the birth, development and in some cases die, technological innovations ranging from typography to the current world of digital printing, through all applied developments to offset, has made an effort in a continuous reinvestment plan, to equip its productive infrastructure with the best tools and technology in the hands of the most prepared professionals.

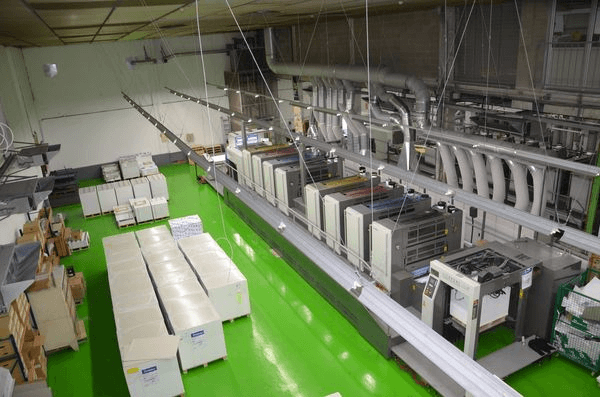

Currently, Vanguard Gràfic it's news again because has been the pioneer graphic company in our country in adopting the new H-UV offset technology, developed by Komori, and materialized in the advanced Lithrone model, with eight colors, which today works at full capacity in the facilities of this Barcelona company.

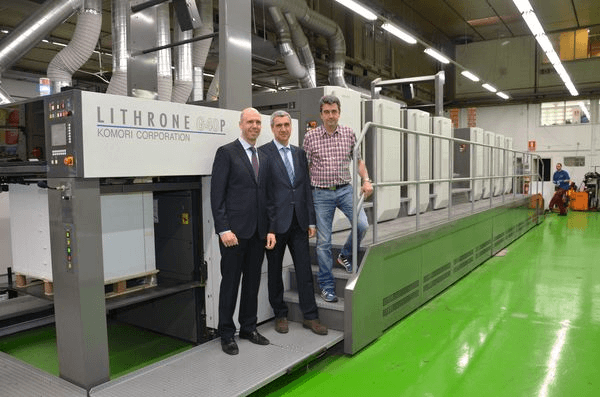

We have had the privilege of visiting the more than two thousand square meters of exemplary facilities, accompanied by Enrique R. Garcia and Enric Cuixeres, Manager and Delegate of the OMC Zone, respectively; accompanied by our hosts: Bonaventura Portavella and Jordi Portavella, Manager and Director of Production, also respectively, at Vanguard Gràfic.

Representatives of the fifth generation of the family at the head of this company, worthy heirs of its founders, maintain a constant effort to demonstrate their commitment to the future, developing continuous long-term reinvestment strategies, applying a philosophy based on achieving the highest quality of the service and providing added value to its customers.

Innovation, total service and commitment

In the 21st century, the highly trained members of Vanguard Gràfic's human team keep alive the values of commitment to the future, honesty, professionalism, dedication, enthusiasm and teamwork.

Thanks to the experience accumulated over the years, and to the enormous willingness to investigate and train as soon as new and usable appears in the field of the graphic industry, the services that Vanguard Gràfic provides to its clients range from initial advice to complete finishing . "Our customer profile", explains Bonaventura Portavella, "Although it is very broad, and ranges from the automotive sector to the fashion sector, passing through the pharmaceutical laboratory, the furniture laboratory, etc., it is characterized mainly by a very high quality requirement".

The infrastructure of this graphic company is at the service of the client's needs from the initial analysis phase, where its technical office is in a position to collaborate and advise on graphic communication projects, develop catalogs, packaging, POS, deal with bases of data for personalization and all this with the latest advances capable of ensuring the best color profiles and print reproduction. In the prepress phase, they provide all the elements aimed at guaranteeing the highest quality, with different tests certified by rigorous regulations.

"Precisely, currently", says Bonaventura Portavella, “One of our immediate projects consists of continuing to shorten the distance that has traditionally existed between the prescriber, the creative or designer of the graphic product, and the printer. We try to get them to visit us, to see what are the possibilities they have when developing their projects, that they can print smells, use volumes, reliefs, textures ... an immense field of possibilities ”.

[youtube] https://www.youtube.com/watch?v=EA7umze0NGs [/ youtube]At the end of the last century, and recurrently in the 21st century, some doomsayers predict the disappearance of print culture, but the good work of Vanguard Gràfic professionals contradicts this threat. For those responsible for this firm, advances like the one they are now taking advantage of, with the new Komori Lithrone H-UV, demonstrate the survival of paper, now with a more vibrant color, and coexisting with innovations such as the inclusion of cross-media performances, augmented reality, and others, "And if we did not believe in what we do, we would not continue investing in offset, since investments in digital technology are always more accessible", says Bonaventura Portavella. This does not mean denying the usefulness of digital printing, and this case at hand is a clear example of the coexistence of the two trends, of their sensible combination to offer the customer what they demand in the best conditions. "To be competitive today", says Jordi Portavella, “You have to find a balance between digital and offset, and in this last section try to be the most efficient. Never say 'no' to the client and look for the proactive solution that meets their needs ”.

A new dimension of offset

One of the most revolutionary advances in offset technology of the last years is Komori's H-UV offset printing system and, once seen, it is not difficult to guess the reasons: time and cost reduction, visual impact and sustainability. "Suppliers always announce great innovations", says Enrique R. García, “And the industrialist who incorporates them must always take the risk of coming up with the right decision. In this case, the most outstanding thing is that Vanguard Gràfic's own clients have noticed the progress and have asked them what they had done to obtain such extraordinary results ”.

One of the most revolutionary advances in offset technology of the last years is Komori's H-UV offset printing system and, once seen, it is not difficult to guess the reasons: time and cost reduction, visual impact and sustainability. "Suppliers always announce great innovations", says Enrique R. García, “And the industrialist who incorporates them must always take the risk of coming up with the right decision. In this case, the most outstanding thing is that Vanguard Gràfic's own clients have noticed the progress and have asked them what they had done to obtain such extraordinary results ”.

The H-UV offset printing system it is very effective in reducing the time between the receipt of the material and the delivery of the product, because finishing processes such as cutting, punching or folding can be carried out immediately. Unlike conventional printing, the waiting times associated with drying the printed material disappear, so a large storage space is not necessary. It reduces the space required to accommodate the increasing number of short runs of different jobs. "We overcome with this", says Jordi Portavella, "The limitations of the output of the printed sheet, the drying phase that, with conventional fat offset, requires drying time by penetration, the use of harmful substances, both for people and for machines, anti-scale powders ... and work ready quickly. But the strong point of H-UV technology is the qualitative and quantitative leap in terms of quality, which is clearly noticed by the end customer even when we have not notified them that we have placed their order using this technology. Color accuracy, almost no dot gain, and all the factors involved improve optical color appreciation, and it is no longer necessary to use coatings, such as varnishes or acrylics, which always 'mask' and distort the reproduction to some extent. printed ”.

Since the H-UV system is mounted inside the printing machine, the power supply is very compact. Also, since does not emit ozone and emits very little heat, it is not necessary to use air conditioning equipment with air ducts. The CO2 emissions from the Komori H-UV system correspond to a quarter of those of a conventional UV curing system: "Environmental and sustainability aspects are crucial today", explains Jordi Portavella, "And the reduction in energy consumption, and the use of materials and consumables that come after recycling is also something that we value positively."

Media that cannot be UV printed due to the potential for heat damage is no longer a problem on an H-UV machine, dramatically expanding the range of jobs the printer can offer. Possible materials include PP, PE, PET, PVC, metallic foil and synthetic paper. "In our dialogue with creatives", says Jordi Portabella, "The ability to print on new supports with this technology is always a strong point".

Compared to conventional UV inks, the H-UV ink has a wider color gamut and higher gloss. Compared with conventional UV varnish, the potential of the high gloss H-UV varnish is higher and its leveling characteristics are superior. And although the point gain is important in the UV process, is extremely low with H-UV inks. In addition, the inks offer good transfer, low viscosity and good machine performance. "Considering everything as a whole", Jordi Portavella concludes, “It is embodied in a complete system capable of achieving higher quality, working faster and being more environmentally friendly. In my opinion it is another generation of level of impressesion in the world of the offset ”.