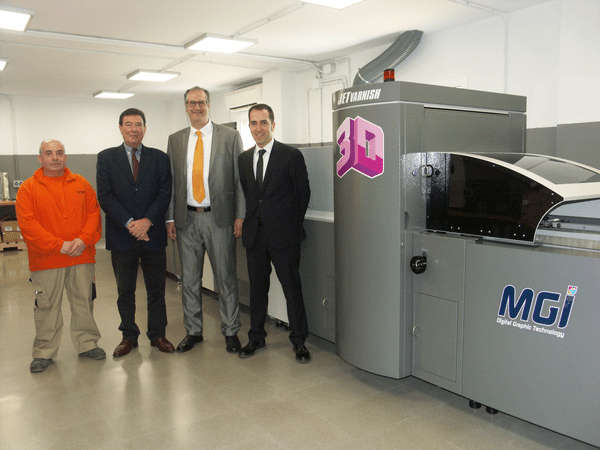

Under the name of newlak, the company Nuenka, located in Barberá del Valles (Barcelona), has launched a new line of activity behind the acquisition of MGI's JETvarnish UV 3D + iFoil UV inkjet coater, in what It is the first installation in Spain of this configuration, the most advanced of the range. The new business unit was created with the aim of offering printing service providers high-quality stamping and varnishing finishes quickly and affordably.

In 1970, Enric Font and Mª Carmen Sentís decided to found Nuenka, a small company located in (Agramunt) Lleida dedicated to the manufacture of textile sleeves for conventional offset wetting rollers that came to respond to a growing demand for services by the graphic arts industry; It should be remembered that, at that time, these types of products were only manufactured in Germany and the United States.

Today, almost fifty years later, with the family business fully consolidated and exporting more than 50% of its production to the whole world from a new 1,200 m2 facility located in Barcelona, his son and current company manager, Jordi Font, has decided to diversify the company's activity by opening a new business unit focused on high-quality digital finishes. “Innovation in our traditional business is already very difficult, -explains the manager of Nuenka- small improvements can be made but little more, so at a certain moment and thinking about the future of our company and the human capital that composes it, we choose for looking for new challenges and opportunities. After analyzing the possible needs of the current graphic market, we opted for a new line of activity based on offering, especially to small and medium-sized companies, a complete service in the field of digital finishes ”.

newlak: the third dimension of varnishing

It is in this process of searching for new opportunities that Jordi Font discover the existence of a digital machine on the market that offered high performance for the subject of finishes and that also perfectly adapted to the business model of the company in terms of offering services to printers. “When I learned about the existence of the MGI machine in the market, I had the opportunity to see it in operation at the Graphics of the Americas 2015 fair. At that time I contacted OMC, as a distributor of these equipment in Spain, and we began to give form this new project, we carried out a market study, I attended demonstrations of it ... until the contract was signed in April ”.

Since the incorporation of the machine, installed last September and operating at full capacity since the beginning of this year, Nuenka offers printers, under the name of newlak, stamping services, 2D and 3D effects, varnishing and in the near future we will incorporate the services that the market will demand of us, such as laminating, guillotine cutting, folding, creasing ... “Our clients are graphic printers who are interested in offering their clients spectacular finishes in any type of work: cards, restaurant menus, book covers, packaging, vinyl for interior decoration, etc. " Jordi Font points out.

And he adds: "The technology in graphic arts advances very fast and although until now it could be thought that this type of finishes and processes were expensive, now thanks to digital technology it can be processed from one copy to the copies that the client needs. a really affordable way. You have to change the mentality of the client and convince him of the quality, versatility and high added value that this type of finish offers at very competitive costs ”.

For the Nuenka manager, one of the greatest attractions of this machine is that can do anything a customer imagines, so they never have to say no to a request. "The machine supports jobs done in any printing system and on a surprising variety of media: paper, cardboard, vinyl, PVC, polyester ... and our goal is to take it to the maximum of its performance, investigating new jobs, different applications, ideas that still they have not been tested ”.

A promising future

The market on which the new service will focus will initially be national, although export is also being considered for a very specific application that is planned to be developed in the near future. "The market to which we are going to focus this machine is obviously not that of large volume, clarifies Jordi Font, but that of those jobs that demand quality, speed and productivity with costs that this machine is in a position to facilitate".

The company's plans go through carrying out specific promotional campaigns for different types of customers where to show them the possibilities they can obtain with the MGI UV digital inkjet coater. “Our objective is to create in the market the need for this type of finishes and treatments for printed media. Look for clients who may come to demand this type of service, who look for different things, with added value in certain types of products, that allow them to distinguish their product in relation to the rest ”.

Highlight the products with a 2D / 3D varnished packaging, applying a gold stamp on book covers, incorporating braille writing, differentiating yourself from competitors by offering another style on business cards ... these are just a small part of the services offered by newlak, which will put everything at the service of customers whatever your imagination may wish for.

Jordi Font concludes by stating: “Despite the economic situation of the sector, or precisely because of it, it was time to look for new projects, to offer an innovative service that was not covered in the market, providing high added value to customers. And, in this sense, the machine is fully meeting our expectations to such an extent that the idea is to acquire, in the not too distant future, a second equipment that, like the current one, incorporates the most advanced technological innovations available in the market. market".

First JETvarnish 3D + iFoil installed in Spain

The machine acquired by Nuenka, la JETvarnish 3D + iFoil UV inkjet coater with reserve and 3D relief plus HotFoil 100% digital is the highest model in MGI's range of digital coaters and the first with this configuration installed in Spain, as pointed out by OMC representatives Michel Madoz, Marketing Director and Enric Cuixeres, Sales Manager: “Although there are two more machines of this type installed in Spain, the model incorporated by Nuenka is the most innovative of the entire range and the first in Spain installed with this configuration, which offers the possibility of stamping as well as varnishing. But also, this machine, with this configuration, is right now the most innovative on the market in terms of finishes and varnishing in a digital process ”they assure.

Enric Cuixeres and Michel Madoz base this statement on the numerous and significant novelties offered by the team, of which the incorporation of double row head that provide more speed and greater varnishing weight, both for 3D effects and even for braille printing, achieving greater relief in a single pass. Another important aspect is the brightness that the machine gives, of a 98%, superior to that provided by the screen printing, which is around the 94-95%. And finally the velocity, which although logically depends on the coverage and relief to be achieved, for the most common coverage on the market, of a 10-15%, it is very high with hardly any waste and on a very wide range of media. "In short, they conclude, it is still common for the market to think that digital systems give less quality than conventional systems, but in the case of varnishing with the digital system offered by this machine, nothing is further from reality".

MGI JETvarnish 3D coater: a benchmark in the sector

MGI's JETvarnish 3D coater is the first digital equipment on the market for reserve UV coating in both 2D and 3D using state-of-the-art inkjet technology. With a 52 × 105 cm format, it is ideal for short, medium and long runs, and is positioned as a benchmark in quality, flexibility and profitability within the graphic arts market.

The equipment has a very fast start-up, do not use plates or screens, does not generate waste, produces between 1 and 3,000 sheets / hour on a wide range of substrates (with sheet widths between 210 and 520 mm and thicknesses ranging from 135 to 600 g / m2) and allows varnishing with three types of finish: gloss, satin and 3D.

The integrated UV curing system of the JETvarnish 3D unit dries the sheets "on the fly" by means of a conveyor belt, without the need to use ozone or solvents, so the sheets arrive completely dry in the high capacity stacker, allowing them to be handled immediately .

Adding the varnish with reserve to any project is very easy because just add a fifth color in the design, highlighting the areas in which the reservation effects should be applied. After printing the document in four-color on any type of machine (digital, offset or flexo), the fifth color is loaded into the integrated station of the JETvarnish 3D system. The piezoelectric heads of the exclusive MGI inkjet technology allow to reproduce lines of only 0.3 mm or that occupy the entire width of the sheet (maximum width 515 mm).