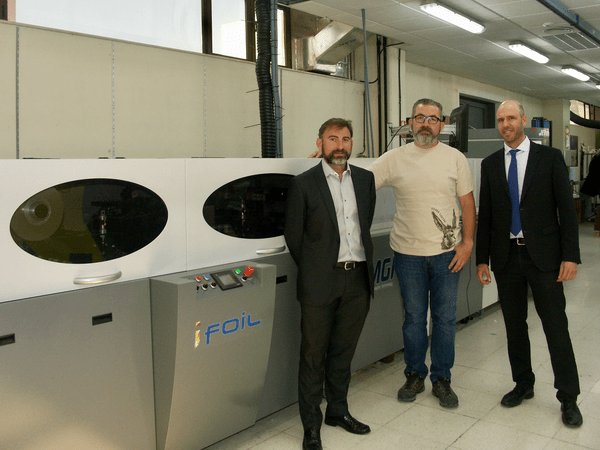

Truyol Digital, a leading company in the sector of digital printing in Spain, has taken another step in its bet on the high-end finishes market with the incorporation of the iFOIL module to its MGI JETvarnish UV 3D digital inkjet coater. Thanks to this investment, the company enters the short-run stamping market, thus increasing the already wide range of services it offers to its customers.

Truyol Digital, a company located in the Madrid town of Alcorcón, began its journey in the mid-eighties after an experience of more than ten years in the world of reprography. The company, specialized in the digital printing sector, in all types of formats and supports, is aimed exclusively at professionals in the graphic industry (printers, graphic designers, design studios ...) and also at advertising, communication and marketing agencies.

With more than 100 devices in its machinery park, a human team of 110 people and 4,440 square meters of facilities, the growth of this company is around 30% per year Thank you “To innovation, the constant search for new markets, products and services, and, mainly, to our priority objective of becoming a reference supplier for our clients based on seriousness, hard work and compliance with commitments. To put it another way, our top priority is to provide our customers with high added value and affordable solutions ” says Joaquín Truyol, manager of the company.

Pioneers in decision

In line with this constant vocation for innovation and search for new markets, Truyol acquired just over three years ago MGI's first JETvarnish UV 3D digital varnishing machine installed in Spain, in what was the first qualitative leap of the company towards the world of high-end digital finishes. Now, this team has been complemented with the incorporation of the iFOIL module thanks to which Truyol adds to its varnishing and 3D finishing services the stamping in short runs, thus increasing the range of possibilities available to its customers. “Finishing is a fundamental aspect in a job and thanks to digital technology it has been possible to incorporate short runs as one more element, something that with conventional technology was not possible or, at least, was not economically recommended. Before we solved these customer requests with a much more complex system, but now, thanks to the digital coating machine and the recently incorporated module, we solve this aspect of the work in more than ninety percent of the cases, in addition to having simplified processes, saving both in terms of time and costs. Basically, it is about using the latest technology to compete with conventional systems that are not comfortable in short runs ” explains the manager of Truyol Digital.

“But the advantages are not only at the technical level, simplification and rationalization of the processes, but it has also allowed us to offer a much wider range of services to our clients, possibilities that we could not undertake before are now within the reach of our clients. in products such as book covers, restaurant menus, magazines, business cards ... without entailing a notable increase in costs. Now we can better absorb orders and do more complex jobs, such as three-tone stamping, that we couldn't offer before. In short, it is about our clients being able to obtain more added value for the same investment, and they are noticing that and are responding in a very positive way " Joaquín Truyol concludes.

Satisfied with the results

In line with the possible response of the market and the clients to this type of finish, the manager of the Madrid company considers that although it is true that there is a wide market for more generalist jobs, it is no less so that there is also a consolidated market for this type of more select products, with more careful, more striking finishes and in small productions. "And the incorporation of iFOIL module to our digital coater JETvarnish UV 3D It has allowed us to further enter this market, offering an efficient and profitable response to this type of customer demand ". “Although all the beginnings, when a new technology is incorporated and especially if you are the first as we were in Spain, require a period of adaptation and adjustment, -aint Joaquín Truyol- today we are very satisfied with the results we are obtaining. The system has been stabilized for a long time and we are working without problems, even with lower costs than expected, for example in the subject of heads, that the forecast was one head per year and the reality is that we have just changed the first head, plus three years later".

"Also, since the incorporation of the AIS Scanner (Artificial Intelligence SmartScanner) to the JETvarnish 3D we have noticed a considerable improvement in the production processes, an improvement in the quality of the register, a reduction in costs, the way of working has been simplified, we have to print fewer sheets to readjust the varnish, stamping or the finish in question ... In short, an improvement in all aspects in terms of productivity, simplicity and reliability. Currently, the machine works almost 20 hours a day, five days a week and we are already considering expanding the human team that is in charge of its operation with a view to incorporating, in the short or medium term, a second team with similar characteristics that allow us to ensure production in the event of any incident ".

Globals in their response

For a company like Truyol Digital, which manages around 350 daily orders, fifty percent of them via the web, mainly national, with more than 5,000 customers and a commitment to deliver between 24 and 48 hours, production automation and flexibility are two Essential aspects for the smooth running of the business that allow them to maintain their high quality standards in terms of customer service. “With the shock of the crisis, and after the pertinent adjustments and restructuring, -reflects Joaquín Truyol- We realized that there was only one way to overcome the situation the sector was going through and that was differentiate ourselves from the rest, offer different things that the market was not doing: we incorporated new technologies and supports, white ink, plastics, different formats, we began to think about die-cuts, we offer practically immediate budgets, delivery times in 24 hours and even on the same day ... And this, in my opinion, can only be achieved if you are responsible for the entire process, if you have the machinery, organization and personnel necessary to be able to resolve any incident practically at the moment ".

As more immediate future projects, Truyol Digital has planned enter the short-run packaging market and relocate the large-format business to other facilities, due to the levels of growth you are experiencing.

MGI JETvarnish 3D coater: a benchmark in the sector

The inkjet coater JETvarnish UV 3D by MGI is the first digital equipment on the market for UV varnishing with reserve both in 2D and 3D that uses state-of-the-art inkjet technology. With a 52 × 105 cm format, it is ideal for short, medium and long runs, and is positioned as a benchmark in quality, flexibility and profitability within the graphic arts market.

The equipment has a very fast start-up, as it does not use plates or screens, it does not generate waste, it produces between 1 and 3,000 sheets / hour on a wide range of media (with sheet widths between 210 and 520 mm and thicknesses ranging from 135 at 600 g / m2) and allows varnishing with three types of finish: glossy, ultra-glossy and satin.

The integrated UV curing system of the JETvarnish 3D unit dries the sheets "on the fly" by means of a conveyor belt, without the need to use ozone or solvents, so the sheets arrive completely dry in the high capacity stacker, allowing them to be handled immediately .

Adding reserve varnish to any project is very easy, as you only have to add a fifth color to the design, highlighting the areas where reserve effects should be applied. After printing the document in four-color on any type of machine (digital, offset or flexo), the fifth color is loaded into the integrated station of the JETvarnish 3D system. The piezoelectric heads of the exclusive MGI inkjet technology allow to reproduce lines of only 0.3 mm or that occupy the entire width of the sheet (maximum width 515 mm).