The Alcorcón digital printer incorporates a 2D and 3D digital varnishing solution, supplied by OMC sae, to the finishing options it offers to its customers.

Truyol Digital is one of the most important digital printing companies in Spain. The company, founded in 1983, is located in the Urtinsa industrial estate in the town of Alcorcón, on the outskirts of Madrid. The more than forty professionals who work at Truyol are specialized in digital printing, in all types of formats and supports, intended for professionals.

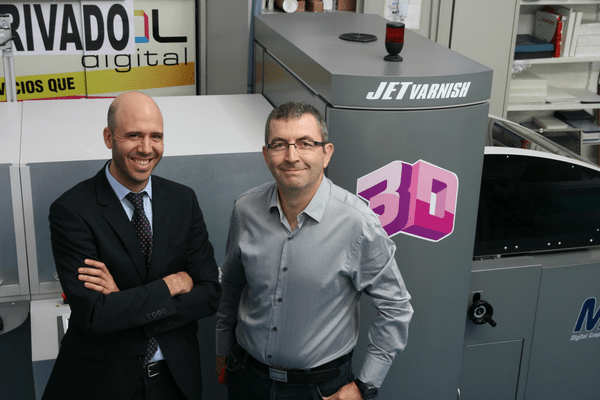

"We already have similar large format varnishing equipment but it is not the right solution for flexible runs and smaller sizes", explains Joaquín Truyol, manager of Truyol Digital. "We also had a solution that we used to make embossed finishes or Braille prints, but it was not practical to work with". Those responsible for the company had already been considering the opportunity to equip themselves with a digital varnishing system for several years. After studying different alternatives, they made the decision to acquire through OMC sae the MGI Jetvarnish 3D. "It is the team that has attracted our attention the most in recent years", explains Joaquín Truyol.

“This team is one more complement to the possibilities we offer. Our idea is to add both printing and finishing options that allow us to offer a lot of unique products ", comments Joaquín Truyol.

The MGI JETvarnish 3D it was installed at the end of the summer. "Being accustomed to digital equipment, the integration of the equipment in Truyol has been carried out in a completely natural way", explains Enrique Rodríguez García, Director General of OMC, sae.

“This machine allows us to apply selective varnishing and 3D finishes on any of the supports that we produce on our digital printing equipment. Both in our Xerox toner equipment and in the HP Indigo ”, says Joaquín Truyol. "We are also offering a varnishing service with the MGI JETvarnish 3D for third parties, although still on a very small scale ”.

The ease of being able to attend very short and very flexible runs in an efficient and agile way is fundamental in Truyol's business development and in the ability to maintain the level of quality in dealing with its customers. In order to Truyol Digital It is essential to have the finishing equipment in the plant since the company's service has, as an outstanding feature, that most of the jobs are produced in the day and, in most cases, and are delivered in a shorter time 24 hours in the peninsula and 48 hours in the Balearic Islands.

At a time when the crisis is reducing the size and results of the printing industry, Truyol is a notable exception with an annual growth of 15%. In the words of his manager: "We have been growing for three years after an approximate drop of 30% in billing".

“With this varnishing equipment and other die-cutting solutions we can do things that with the current economic moment are not feasible with other types of processes. When we were rich you could ask, for example, 300 euros to apply a varnish finish on a job, and the client paid it without problem. Now, the client is going to say no to you. With the runs and budgets that are handled now this is unfeasible with more traditional processes. The UV inkjet coater MGI JETvarnish 3D allows you to adjust production and cost in a much more efficient and adjusted way. Thus, the client who wants something special, which there are, has options to be able to have it in line with their current budgets ", says Joaquín Truyol.

This team will facilitate that many of the company's clients can offer a service with a lot of added value without increasing their costs in an excessive way. "Now our clients will be able to offer very high quality finishes and great added value at very affordable prices", says Joaquín Truyol. In line with the philosophy of the company: "Sell value-added product, which was previously an expensive product, making it profitable so that my clients' clients can count on attractive and affordable solutions".

“It was at Graphispag Digital 2013 where we officially presented and launched the new Jetvarnish 3D at the national level. During the Fair we were able to verify "in-situ" the excellent acceptance and interest generated by its combined 2D and 3D finish in a single pass. Many were the printers, graphic designers ... who asked us where to order or carry out high-value-added finishes such as those seen in the different demonstrations carried out during the event " comments Michel Madoz, Marketing Director of OMC, sae.

"In order to offer innovative solutions that improve competitiveness and survival possibilities, it is necessary to continue looking for options that allow differentiation in terms of product together with cost optimization", indicates Michel Madoz.

“In the end, if you offer service, seriousness at work, a variety of products that add value, that provide a benefit to the customer, and you try to make things easier for customers; you find your space in the market ", concludes Joaquín Truyol.

With the JETvarnish 3D system, UV varnishing with reserves takes on a new dimension, thanks to higher performance in UV varnishing jobs and incredible 3D effects with volume.

Ideal for operations with offset or digital printing machines up to 52 × 105 cm., Giving printers the possibility of offering true value-added services. MGI JETVarnish 3D has a very fast start-up since it does not use plates, screens or generates waste, and produces up to 3,000 B2 sheets per hour (UV coating with reserve), accepting a wide range of supports, allowing varnishing, in the same document and in a single pass, with a glossy, ultra-glossy or satin finish; and 3D relief with varnish thicknesses from 3 to 100 microns, depending on the areas defined by the user.

"In short and ultra-short runs, MGI's JETvarnish 3D allows UV varnishing to be applied at very competitive costs", reaffirms Enrique Rodriguez García, Director General of OMC, sae